Laser matrix materials are the cornerstone of solid-state laser technology—they act as host mediums that let us precisely control and amplify coherent light. These sophisticated materials need to meet tough optical, thermal, and mechanical requirements at the same time—they also have to create an optimal environment for laser-active dopant ions. Choosing and engineering the right matrix materials directly affects how well a laser performs—things like power output, beam quality, efficiency, and how reliable it is.

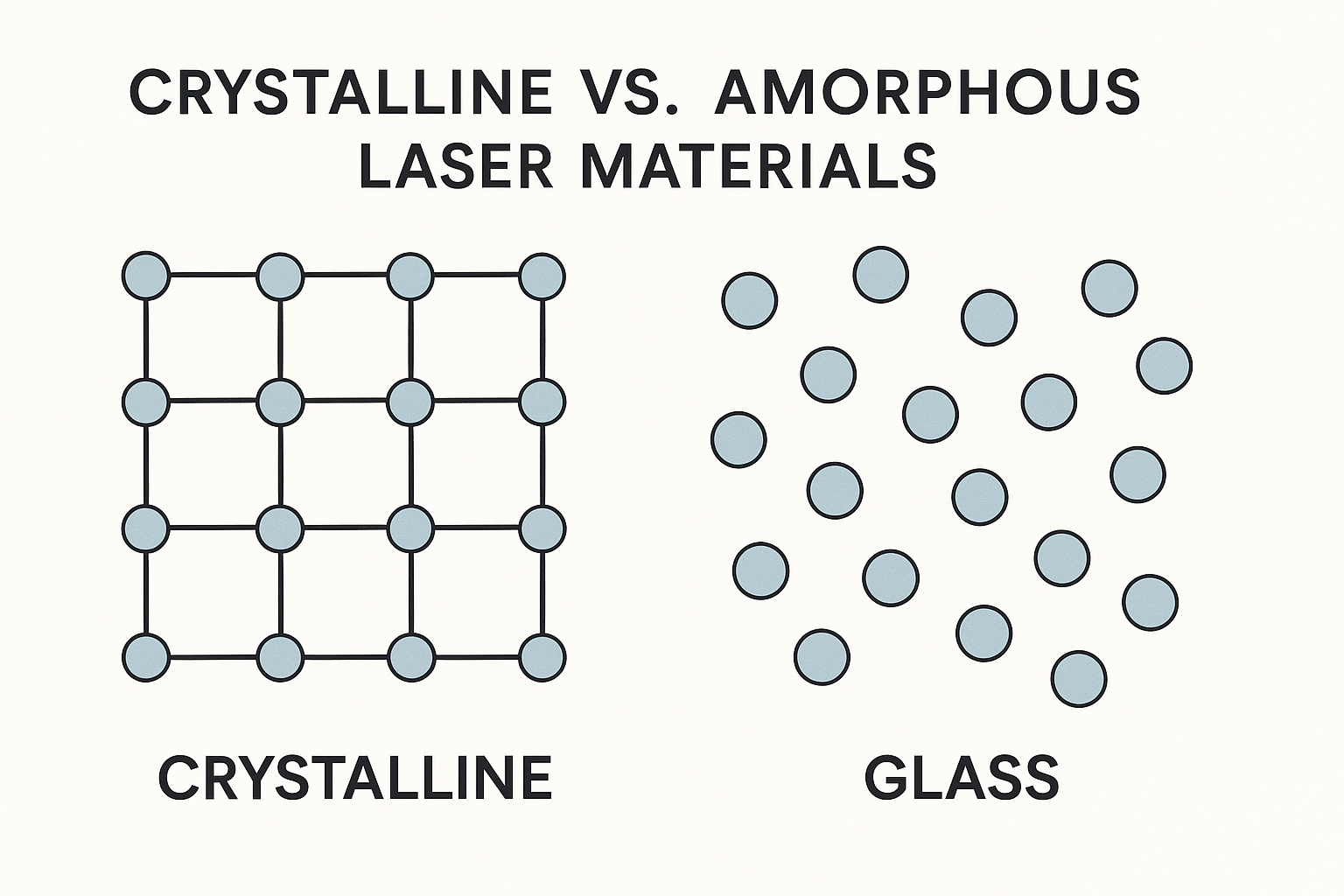

Solid-state laser matrix materials fall into two main structural categories: crystalline and amorphous glass. This split shows big differences in how atoms are arranged, physical properties, and what lasers they’re used in.

Crystalline materials have highly ordered, periodic atomic structures—this gives them excellent optical homogeneity and great thermal management. Examples like neodymium-doped yttrium aluminum garnet (Nd:YAG) and titanium-doped sapphire (Ti:Sapphire) have amazing thermal conductivity—between 5 and 35 W/mK. The ordered structure lets us control dopant ion environments precisely—It also helps dissipate heat efficiently when lasers run at high power.

Amorphous glass materials, on the other hand, have disordered atomic structures—they’re better for manufacturing flexibility and cost. Phosphate and silicate laser glasses are easy to make in large amounts using simple melting processes—this makes them perfect for high-energy pulsed lasers. But their lower thermal conductivity (usually 0.5-2 W/mK) means they can’t be used in continuous-wave high-power systems.

Modern lasers work in tough environments—they need matrix materials with great all-around properties. These needs include optical transparency, thermal management, mechanical strength, and chemical stability under intense radiation.

Great optical properties are the base of how well a laser matrix material works. The material needs to stay highly transparent (>90%) on the right spectral range—It also has to keep scattering losses below 0.1% per centimeter. Refractive index uniformity is key—if it varies more than 10⁻⁵, the beam gets distorted and the laser output quality drops. Also, the material has to handle optical damage thresholds over 1 GW/cm²—this lets lasers run at high intensity without breaking down.

Good thermal management decides how much power a laser system can handle. For continuous-wave lasers, matrix materials need thermal conductivity over 5 W/mK—top crystalline materials can reach 35 W/mK. Thermal expansion coefficient needs to be below 15×10⁻⁶/K—this reduces thermal stress. Thermal shock resistance should be over 10 W/cm to stop fractures from rapid temperature changes.

Mechanical properties directly affect how reliable a laser system is and how long it lasts. Matrix materials need to have hardness over 5 on the Mohs scale—top crystals reach 8-9 for maximum durability. Fracture strength usually needs to be over 100 MPa—this helps handle mechanical stress during use and handling. Chemical inertness keeps the material stable long-term under laser radiation and environmental exposure.

How dopant ions interact with the host matrix decides how efficient the laser is and how well it performs spectroscopically. To add laser-active ions successfully, you need to think about size compatibility, valence matching, and crystal field effects.

For the best laser performance, dopant and host ion characteristics need to match precisely. Ionic radius difference should be within ±15%—this reduces lattice strain and keeps crystal quality high. Valence state matching is just as important—if charges are unbalanced, it creates unwanted defects and lowers laser efficiency. For example, trivalent neodymium ions (Nd³⁺) replace trivalent yttrium ions (Y³⁺) in YAG crystals—they’re similar in size and have the same charge.

The local crystal field around dopant ions decides the energy level structure and how likely laser transitions are. Symmetric crystal field sites make radiative transitions more efficient—they also reduce non-radiative decay. Crystal field strength needs to split energy levels appropriately—this creates good conditions for laser operation, like population inversion and optimal transition cross-sections.

Choosing modern laser matrix materials means evaluating multiple performance criteria systematically. These criteria include spectroscopic properties, structural compatibility, how easy it is to manufacture, and cost.

Laser-active dopant ions need stimulated emission cross-sections close to 10⁻²⁰ cm²—this makes light amplification efficient. Fluorescence lifetimes should be over 100 microseconds—this lets you store energy effectively and use Q-switched operation. Energy level structure needs to support good population inversion—It also has to reduce unwanted absorption and quenching.

Host crystal structure needs to have lattice sites that can hold dopant ions—It also has to keep crystal field symmetry optimal. Site symmetry directly affects transition selection rules—It decides which laser transitions are allowed. High-symmetry sites usually give the best conditions for laser operation—they reduce inhomogeneous broadening and optimize transition probabilities.

For practical laser uses, materials need to be made with consistent quality and at a reasonable cost. Crystal growth techniques need to make large, high-quality boules with uniform dopant distribution. Manufacturing processes should keep dopant concentration uniform within ±2%—They also have to maintain optical quality factors over 10⁴.

Modern laser technology pushes for constant innovation in matrix material development. Advanced crystal growth techniques let us control composition and microstructure precisely—this improves performance.

Modern research looks at new host materials with better thermal and optical properties. Rare-earth sesquioxides have great thermal conductivity—they also have broad emission bandwidths that work for ultrafast lasers. Advanced dopant combinations (like co-doping) let you tune wavelengths and optimize performance for specific uses.

Polycrystalline laser ceramics have manufacturing advantages—they’re almost as good as single crystals in performance. These materials let you produce large amounts with controlled dopant distributions—they’re cheaper than conventional crystal growth. Composite materials with multiple active species have better functionality for specialized laser uses.

Laser matrix materials are where materials science, crystal chemistry, and optical engineering meet. Choosing between crystalline and glass matrices decides what a laser system can do—crystals are best for high-power continuous use, while glasses rule high-energy pulsed systems. To choose the right matrix material, you need to evaluate optical, thermal, mechanical, and spectroscopic properties—you also have to think about ion-host compatibility and manufacturing limits.

As laser technology moves toward higher powers, shorter pulses, and new wavelengths, matrix material development is key to making these breakthroughs happen. Improvements in crystal growth techniques, compositional engineering, and structural optimization will keep improving laser matrix material performance and capabilities.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China