Four-level laser systems are an key advancement on laser tech. They work much better than traditional three-level setups—more efficient and higher performance. These complex systems are common in rare earth-doped crystals and glass. They’ve changed modern laser uses by fixing problems in older designs. Adding an extra energy level on purpose creates perfect conditions for population inversion. It also cuts down on threshold power needs and makes continuous wave operation better.

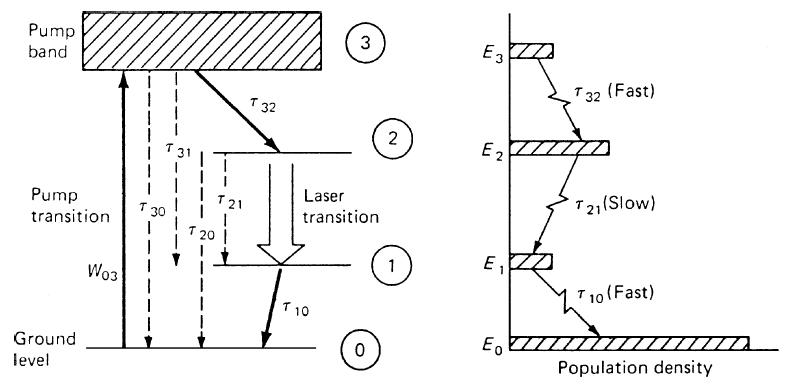

Four-level lasers have a key design upgrade—four separate energy states. These are ground state (E₀), lower laser level (E₁), upper laser level (E₂), and pump level (E₃). This setup is very different from three-level systems. It uses laser transitions between two excited states, not between an excited state and ground state. Putting lower laser level E₁ above ground state E₀ on purpose makes it easier to keep population inversion. You need an pump power too.

The energy level design lets population cycle efficiently. It uses carefully built transition paths. Pump radiation pushes atoms from ground state E₀ to upper pump level E₃. There, they quickly decay (without radiation) to the metastable upper laser level E₂. Level E₂ is metastable—so atoms stay there longer. Usually microseconds to milliseconds. This lets a lot of population build up. Laser action happens when stimulated emission moves from E₂ to E₁. Then E₁ quickly relaxes back to ground state E₀.

Four-level systems get population inversion between two excited states. This changes the thermodynamic needs for laser operation completely. Three-level systems need to overcome a big ground state population for inversion. But four-level setups only need a little population in upper laser level E₂. That’s enough to beat the tiny population in lower level E₁. This design advantage cuts threshold pump power a lot. Often 5 to 10 times less than similar three-level systems.

How four-level systems work over time depends a lot on the lifetimes of their energy levels. For best performance, the time it takes E₁ to relax to ground state (τ₁₀) must be much shorter than the laser transition’s fluorescence lifetime (τ₂₁). Usually τ₁₀ << τ₂₁. This timing setup makes sure E₁ loses population fast. It keeps good inversion conditions even when stimulated emission is high.

Real four-level operation needs precise design of energy level gaps and transition chances. Lower laser level E₁ must have very little thermal population. So it needs a big enough energy gap from ground state. That way, Boltzmann statistics keep thermally excited population low. If a material has an small gap between E₁ and E₀, you might need cryogenic cooling. It stops thermal population and keeps four-level features.

Upper laser level E₂ is metastable—so it needs a long lifetime. That way, population can build up and store energy. Usually, upper level lifetimes are hundreds of microseconds to a few milliseconds. It depends on the ion-host mix and crystal field. Fast non-radiative transitions from pump level E₃ to E₂ make population transfer efficient. They also cut down on other decay paths.

An big difference between three-level and four-level lasers is how they get population inversion. And how efficient they are. Three-level systems need to beat a big ground state population. So they need high pump rates to hit the 50% inversion threshold. This means higher threshold power, lower slope efficiency, and trouble keeping continuous wave operation.

Four-level systems avoid these problems. They get inversion between two excited states—lower level has very little population. This setup lets lasers run on very little pump power. Often, they get close to theoretical quantum efficiency limits. Population cycles continuously through the four-level system. This supports stable continuous wave operation—no thermal management problems like three-level systems with high thresholds.

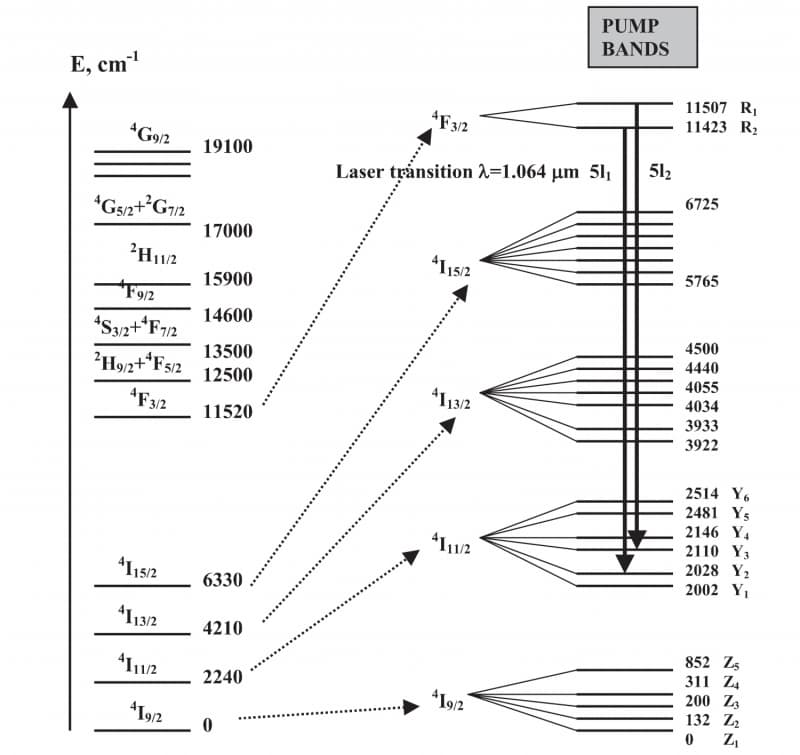

Modern four-level lasers use many different materials. Each is optimized for specific uses and needs. Rare earth-doped materials are the most common in four-level lasers. They have good energy level structures and long metastable states. Neodymium-doped systems like Nd:YAG and Nd:YVO₄ are great examples. They work really well—super efficient and can scale up power.

They get slope efficiencies over 50% with threshold power under 100 milliwatts. That lets them run at kilowatt-class continuous wave. Helium-neon gas lasers are another successful four-level type. They use collisions between helium and neon atoms to get population inversion.

To math out how four-level lasers work, you use coupled rate equations. These describe population densities and photon flux in the laser cavity. When things are steady, the rate equations get a lot simpler. That’s because pump and relaxation levels balance out fast. Population inversion density (N = N₂ - N₁) sets the small-signal gain coefficient. Photon density controls the stimulated emission rate.

When analyzing threshold, laser oscillation needs optical gain to exactly balance cavity losses. This balance point sets the threshold population inversion and the pump power you need. Above threshold, gain clamping keeps inversion density constant. Extra pump power turns into laser output—efficiency depends on slope efficiency.

Four-level lasers use many different pumping methods. Each is tailored to the material’s properties and what the laser is used for. Optical pumping uses diode lasers or flashlamps. It excites the laser medium at specific wavelengths that match its absorption bands. How well pump radiation matches the absorption features sets pump efficiency and thermal loading.

Electrical pumping with discharge works well for gas four-level systems. Electron impacts and collisions transfer energy to get population inversion. Chemical pumping and other unusual methods have been tested. They’re for special uses that need high energy or unique operation.

To optimize four-level laser efficiency, you need to think about many linked parameters. These include pump absorption, quantum efficiency, and output coupling. How well pump absorption works depends on how much the pump beam profile overlaps with the medium’s absorption cross-sections. Quantum efficiency shows how likely it is that absorbed pump photons transfer energy to the upper laser level.

Optimizing output coupling means balancing two things: low threshold power and high slope efficiency. They compete with each other. The best output coupling depends on laser gain, internal losses, and what the laser is used for. Advanced designs use variable output coupling or multiple ports. This lets them work best in different operating conditions.

Four-level lasers are used a lot in science, industry, and medicine. That’s because they’re more efficient and work better. High-power industrial uses get benefits from four-level systems. They’re scalable and easier to manage thermally. Medical uses take advantage of four-level lasers. They have precise wavelength control and stable operation.

New developments in four-level lasers are focusing on new materials, better pumping, and integrated photonics. Ceramic laser materials are easier to make. But they still work as well as single crystals. Fiber-based four-level systems are small and tough. They have great beam quality and thermal management.

Four-level lasers are a mature technology, but they’re still evolving. They’ve completely changed laser science and how we use lasers. Adding an extra energy level on purpose creates perfect conditions for efficient inversion. It cuts threshold needs a lot and makes operation better. We understand four-level dynamics really well—from energy level design to practical use. This keeps driving innovations in lasers and expanding what coherent light can do.

As material science gets better and manufacturing improves, four-level lasers will keep being the foundation for next-gen lasers. They’ll be used in many different areas.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China