UV laser deliver durable, high-contrast coding, ensuring secure track-and-trace for pharmaceutical, medical, and cosmetic products throughout their lifecycle.

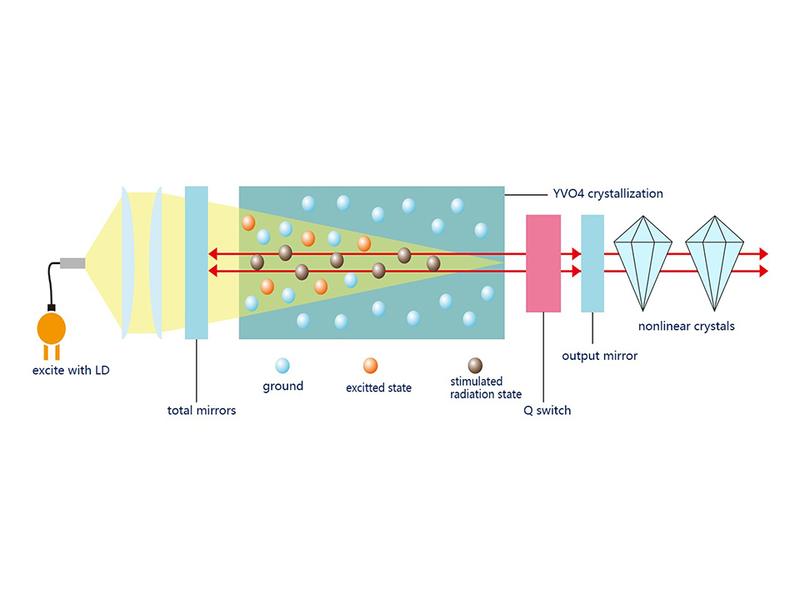

The wavelength of the ultraviolet laser is 1/3 of the basic wavelength (1064nm), and it is a laser in the ultraviolet region, so it is called “ultraviolet laser printer”. In addition, it is also known as THG (Third Harmonic Generation) laser. The fundamental wavelength is converted to a wavelength of 532 nm plus the basic wavelength through a nonlinear crystal, and then converted to a wavelength of 355 nm by another single crystal. The absorption rate of each material is very high, and because it can be marked and processed without heat stress, this type of marking is called “cold marking”.

The wavelength of the light greatly affects the spot diameter of the laser. Since the UV wavelength (355 nm) is 1/3 of the basic wavelength (1064 nm), the spot size can be concentrated even in a small area, making it possible to mark even in a confined space.

PET packaging producers are increasingly using “thin-walled” PET in an attempt to reduce costs and waste. This creates difficulties for laser marking, as thinner materials can burn through. Choosing a UV Laser printer solves this challenge by producing alternative marking effects.

At the same time, in the context of strengthening the laws and regulations related to the use of drugs, there are also increasing cases of switching from ink to laser marking.

High-density polyethylene (HDPE) bottles continue to be one of the premier packaging solutions for pharmaceutical products, requiring labeling on the bottle body to facilitate product tracking. UV Laser printers can mark dark, long-lasting, high-resolution codes on a light-colored HDPE background that is also visually readable.

Photolysis treatment inhibits damage

UV Lasers have a large energy of photons, and can be used to directly cut off the intermolecular bond. Therefore, without heating the surface, it is possible to perform marking and processing to suppress damage.

Photolysis treatment inhibits damage

It also has a high absorption rate for materials with high reflectivity, such as gold, silver, and copper, and does not generate unnecessary thermal stress. As a result, it is possible to suppress the generation of soot and burrs without damaging the surface state, and to achieve high corrosion resistance for marking and processing.

Photolysis treatment inhibits damage

As electronic parts become smaller year by year, the thickness of the packaging resin part is also decreasing. If a basic wavelength laser (1064nm) is used, it may pass through the encapsulation resin and cause internal damage. If a UV Laser (355nm) is used, it can suppress the penetration of the laser into the interior with a high absorption rate.

The ultraviolet laser marking machine is suitable for all materials that have adverse reaction to heat, such as food, pharmaceutical packaging materials, silicon wafers, LCD screens, etc. The marking uses a 355nm ultraviolet laser, which hits the surface of the substance with a laser beam, and directly breaks the molecular chain of the substance through a short-wavelength laser, so as to achieve marking and engraving.

It can code on metals, plastics, ceramics, glass, rubber, textiles, masonry, corrugated paper, flexible films, foils, labels, and more.

Its advantages are high precision, high efficiency, low noise, low energy consumption, and the marking effect is long-lasting and does not fade. It is especially suitable for use in food, medicine, daily chemical and other industries to empower the production of Industry 4.0.

The main application scenarios of UV Laser coding machine:

1. Food industry: avoid air leakage caused by laser penetration through the outer packaging when coding.

2. Pharmaceutical industry: to achieve high color and no thermal damage coding, at the same time with visual readability, in line with the corresponding regulations and standards.

3. Sanitary products industry: use cold light source for coding, and refuse dust explosion caused by coding

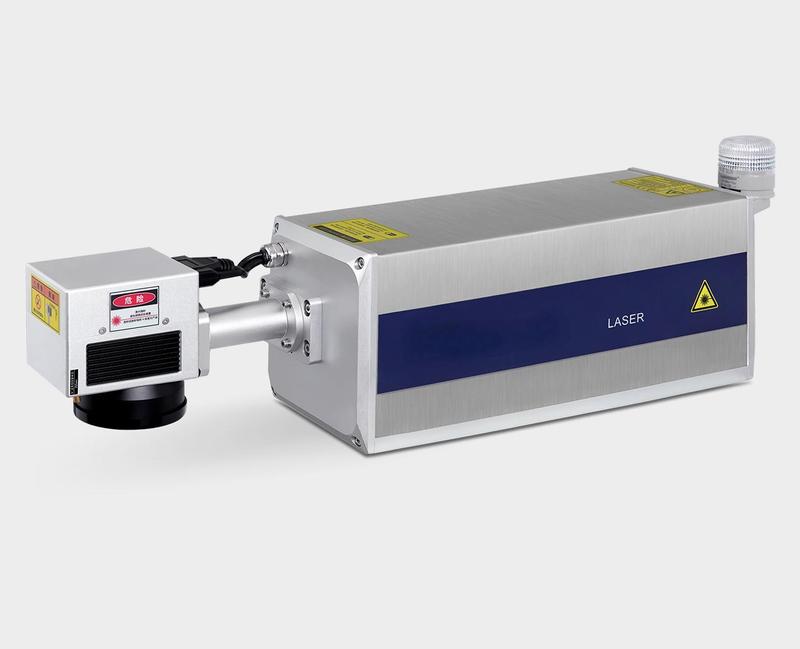

Each UV Laser printer comes standard with the core and accessories including the following:

Lasers, electric control boxes, encoders, water cooling boxes, alarm lights, photoelectric sensors, touch all-in-one machines, lifting brackets, some wires and manuals, etc. In addition, customized accessories can also be equipped according to customer needs.

| Parameter | NN-UV803i | NN-UV805i | NN-UV810i |

|---|---|---|---|

| Laser details | |||

| Laser type | Q-switched pulsed lasers | ||

| Maximum output power | 3W | 5W | 10W |

| Laser wavelength | 355nm | ||

| Laser tube lifetime (average)* | 15000 hours | ||

| Laser class | Class 4 laser products comply with IEC60825-1 standard | ||

| Performance | |||

| Maximum linear speed | 20m/s | ||

| Marking speed | Up to 30 characters/sec | ||

| Coding angle | Downward (90°) or flat (0°) | ||

| Mark the area | Coding Elliptical Areas:70 x 70mm、100 x 100mm、140 x 140mm、200 x 200mm | ||

| Marking heads and lenses | |||

| Vibrometer | 8mm、10mm | ||

| Beam expanders | 2~10 multiples Conventional 6 multiples | ||

| Spot size | 20μm | ||

| Mark the distance | 255~265mm | ||

| Interface/Interface | |||

| Operator interface | Built-in 10 inch touch screen of win10 system | ||

| Communication interfaces | One Ethernet RJ45 port, one serial RS232, RS485, USB, SD card | ||

| Operating environment | |||

| Rated voltage | 200 – 240V 50/60Hz | ||

| The power of the whole machine | 300W | ||

| Ingress protection | IP54(standard)和IP65(Matching) | ||

| Operating temperature | 5~45℃ | ||

| Humidity range | 80% max (relative humidity, non-condensing) | ||

| Cooling method | Water cooling | ||

| Product quality | Optical path weight: 21.3Kg Power weight: 8.4Kg Water tank weight: 29.5Kg | ||

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China