The fiber laser marking machine is designed to meet the needs of manufacturers working with hard, high-density packaging materials on medium- or high-speed production lines.

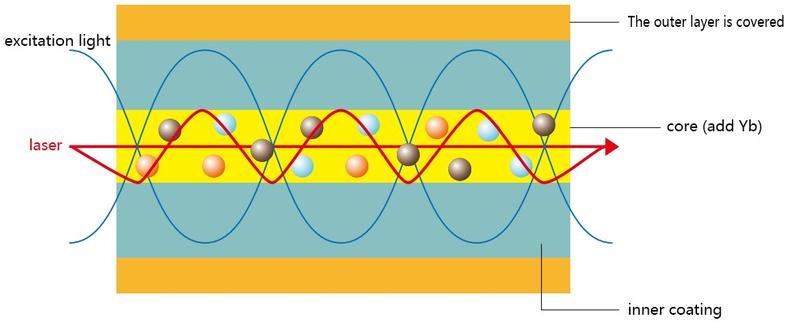

Fiber lasers use optical fibers as the medium, which is the product of the development of interrupt amplification technology for long-distance communication into high-power output lasers. An optical fiber consists of a core that transmits light in the center and a metal cladding that wraps the core in concentric circles. The fiber laser uses this core as the laser medium to amplify the light. Hence Yb (Ytteribum, ytterbium) is added to the core.

The amplifier fibers (preamplifier, main amplifier) are constructed in three layers, including the core and two layers of metal cladding. The excitation light enters the inner metal cladding (inner coating) and the core with Yb added, so that the atoms inside the core are transformed into excited states. The laser is enclosed in the core and then amplified by the excited atoms, and the more it advances in the medium, the stronger it becomes. Unlike solid-state lasers or gas lasers, light travels in one direction and does not go back and forth.

High-power fiber lasers are ideal for high-wear products such as engine components, ball bearings, braking systems or extruded products and cables, where clear marking contrast and durability ensure that the codes are legible throughout their entire lifecycle.

The laser source has a longer service life, with a mean time between failures (MTBF) of about 100,000 hours;

The air-cooled laser source is virtually maintenance-free and has no wearing parts, significantly reducing downtime;

Standard 100*100 marking area, as well as high marking accuracy and edge sharpness to achieve higher throughput;

Standard IP54 protection level, suitable for continuous and stable operation in dusty and humid harsh environments;

A variety of working distances are optional, 0~360 degree printhead installation direction, and the production line integration is more flexible.

The marking material, the laser wavelength and the type of laser all affect the marking effect. Here are a few of the effects of fiber optic coding.

Melting different plastic materials to achieve a concave and convex effect;

The chemical reaction between the laser and the product results in a change in color;

Marking on the surface of the product, e.g. cans and on metal;

Ablation or removal of surface coating color to expose the underlying replacement color;

Carbonization or controlled combustion of wood or cardboard materials, as well as cables and pipes.

A fiber laser is a device that uses a high-energy laser beam generated by a fiber laser to permanently mark the surface of various materials. It is based on the principle of evaporation, chemical change or ablation of the surface of the target substance by a laser to engrave the desired pattern, text or QR code.

Fiber laser printers can be applied to metallic and non-metallic materials, including aluminum, stainless steel, copper,

iron, steel, alloys, ceramics, glass, plastics, rubber, wood, paper, etc. Its marking effect is clear, beautiful, durable, anti-counterfeiting, and suitable for various industries, such as electronics, machinery, automobiles, communications, food, packaging, etc.

Fiber laser markers are designed for marking hard, high-density packaging materials on medium or high-speed production lines, such as metal parts, electronics housings, wires and cables, cans, and plastic bottle caps.

Each fiber laser printer comes standard with the core and accessories including the following items:

Lasers, electric control boxes, encoders, photoelectric sensors, touch all-in-one machines, lifting brackets, some wires and manuals, etc. In addition, customized accessories can also be equipped according to customer needs.

| Parameter | NF720i | NF730i | NF750i |

|---|---|---|---|

| Laser details | |||

| Laser type | Ytterbium-doped fiber lasers | ||

| Maximum output power | 20W | 30W | 50W |

| Laser wavelength | 1064nm | ||

| Laser tube lifetime (average)* | 100000 hour | ||

| Laser class | Class 4 laser products comply with IEC60825-1 standard | ||

| Performance | |||

| Maximum linear speed | 20m/s | ||

| Marking speed | Up to 30 characters/sec | ||

| Coding angle | Downward (90°) or flat (0°) | ||

| Mark the area | Code the elliptical area[mm]:70 x 70、110 x 110、145 x 145、175 x 175 | ||

| Marking heads and lenses | |||

| Vibrometer | 8mm、10mm | ||

| Spot size | 60μm | ||

| Mark the distance | 110~275mm(Customizable) | ||

| Interface | |||

| Operator interface | Built-in 10 inch touch screen of win10 system | ||

| Communication interfaces | One Ethernet RJ45 port, one serial RS232, RS485, USB, SD card | ||

| Operating environment | |||

| Rated voltage | 200 – 240V 50/60Hz | ||

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China