Laser pulse generation has evolved from nanosecond Q-switched systems to femtosecond mode-locked setups. This shift stands as one of photonics technology’s most significant advances. It has brought unprecedented precision to scientific research, medical procedures, and industrial applications—fundamentally changing how we use light for ultrafast processes.

Conventional laser systems—especially those with standard-length resonators—use Q-switched operation to make pulses lasting 10 to 20 nanoseconds. Cavity length fundamentally limits pulse width here: resonator size directly shapes the time traits of these pulses. This link comes from light’s round-trip time on the optical cavity, which sets the smallest possible pulse duration for Q-switched setups.

Advanced cavity emptying techniques can cut the minimum pulse width to around 1-2 nanoseconds. But this improvement adds more system complexity. Physical cavity length still limits things—it decides the least time needed to pull all energy from the gain medium. These limits show why Q-switching falls short when you need ultrashort pulses.

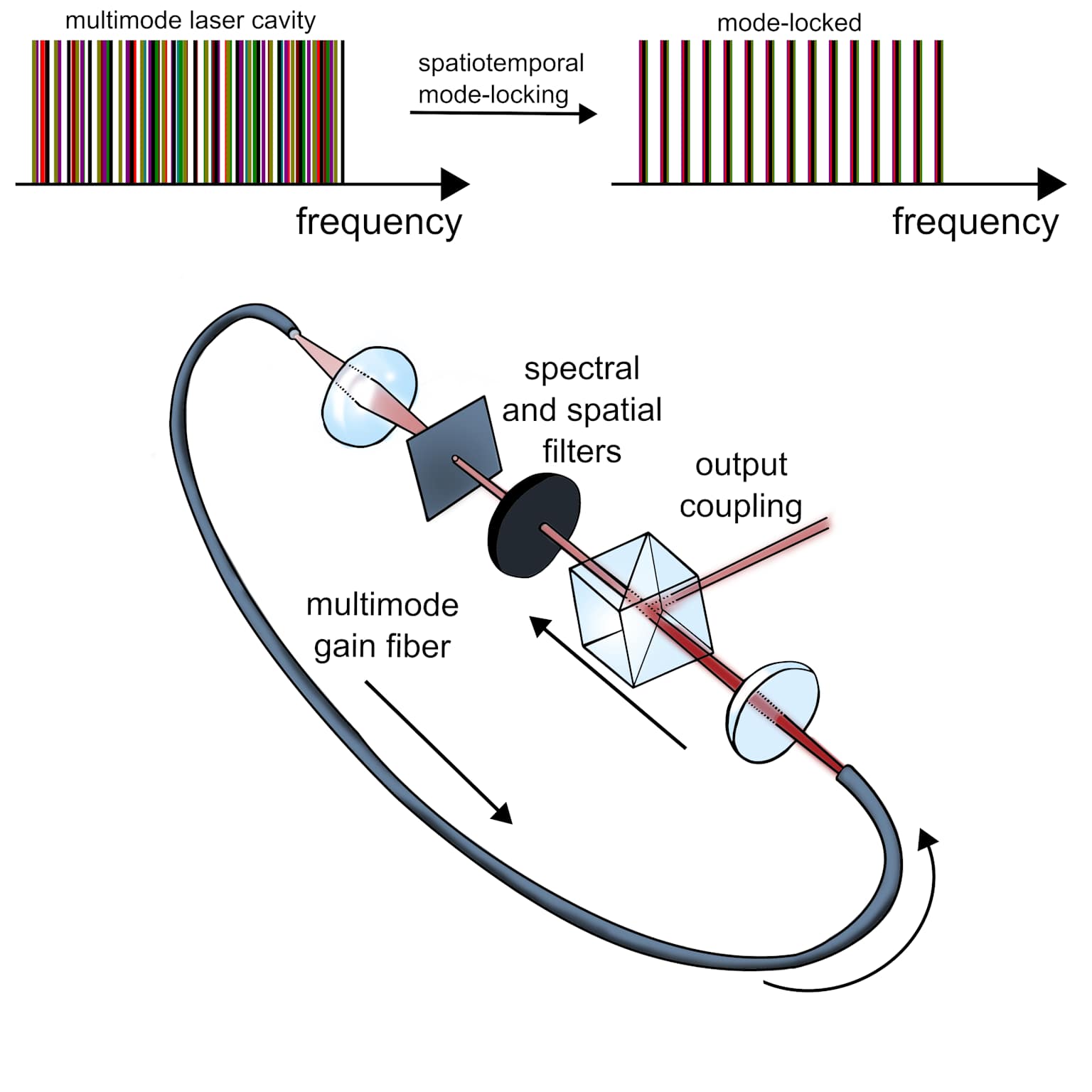

Mode locking changes the game for pulse generation. It lets solid-state lasers make ultrashort pulses—picosecond or femtosecond long. The trick? Setting fixed phase links between the laser cavity’s longitudinal modes. This syncs multiple frequency parts to build coherent pulse trains.

Mode locking’s core principle is the inverse link between pulse width and the laser medium’s optical bandwidth. You can write this as Δt ∝ 1/Δν—Δt is pulse duration, Δν is bandwidth. This is why broadband gain media are key for making the shortest pulses possible.

Passive mode locking uses the interaction between circulating laser light and saturable absorbers—materials where absorption changes with intensity. The absorber makes periodic modulations that set fixed phase links between longitudinal cavity modes. This leads to stable pulse formation.

True saturable absorbers have limited absorption centers—like organic dyes or semiconductor structures. They turn transparent when hit by high-intensity radiation.

Modern passive mode locking systems often use semiconductor saturable absorber mirrors (SESAMs). They offer engineerable saturation traits and better reliability than organic dye setups. These devices have semiconductor Bragg mirrors with embedded quantum well structures—they act as saturable absorbers. This gives precise control over modulation depth and recovery time.

You can also make effective saturable absorbers using nonlinear optical mechanisms. These use the intensity-dependent refractive index and spatial beam traits of optical materials. Kerr lens mode locking (KLM) is a sleek take on this. Here, the nonlinear Kerr effect in the gain medium itself acts as an artificial saturable absorber.

Active mode locking uses external modulators—usually acousto-optic devices—to add precise phase or frequency modulation at the cavity’s round-trip frequency. This method gives more gain to mode-locked pulse trains than continuous-wave operation. Why? The modulation syncs with the cavity’s natural resonance.

Acousto-optic modulators work by making traveling acoustic waves in transparent crystals. These waves create periodic refractive index changes that diffract the laser beam. If you drive them at frequencies matching the gap between adjacent longitudinal modes, the modulators lock the phases of multiple cavity modes. This makes stable pulse trains.

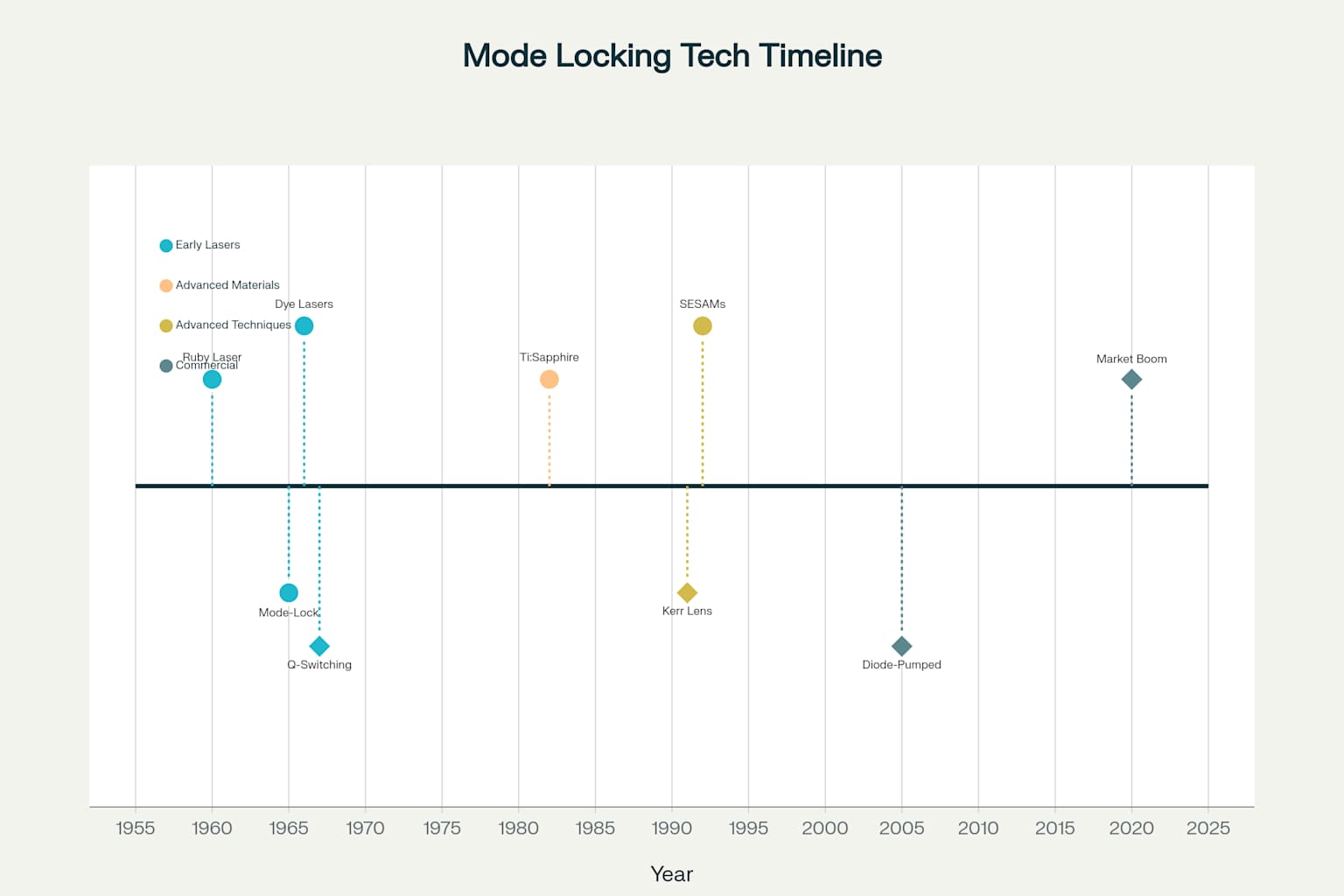

Mode locking technology got its start in the mid-1960s. Scientists showed it working in solid-state lasers using organic dyes as saturable absorbers. Early setups used flash lamp-pumped ruby, glass, and Nd:YAG lasers to make picosecond pulses. All relied on saturable absorber mechanisms.

But these early systems had big problems: poor repeatability and unstable output. The issue? Organic dye solutions’ inherent limits. Dye-based saturable absorbers had a bad habit—they’d do both mode locking and Q-switching at the same time in pulsed solid-state lasers.

Every pump pulse made multiple mode-locked pulses inside the Q-switched envelope. This led to complex time structures and unpredictable output. Pulse buildup from noise was random—plus dye degradation and photochemical instability. All this caused big output variations.

Because of these reliability issues, researchers turned to continuous-wave dye lasers. These had the broad gain bandwidth needed for femtosecond pulses. Dye lasers’ large gain-bandwidth product, plus better mode locking techniques, let them make pulses as short as tens of femtoseconds.

Dye lasers had operational headaches—handling and maintenance were tough. But they stayed the main platform for ultrafast research for years.

Tunable solid-state laser materials—especially titanium-sapphire crystals—changed ultrafast laser tech forever. Titanium-sapphire has a gain-bandwidth product as good as or better than organic dyes. That makes it perfect for femtosecond pulses—plus it’s stable and robust, like solid-state systems should be.

Kerr lens mode locking (KLM) was developed just for titanium-sapphire systems. It set a new standard for femtosecond research. Argon-pumped titanium-sapphire lasers using KLM became the gold standard for ultrafast apps. Later, they evolved into all-solid-state setups using frequency-doubled Nd:YAG pump lasers.

Semiconductor saturable absorber tech was another big win for passive mode locking. Diode-pumped solid-state lasers—like Cr:LiSAF—now use these absorbers to make compact, robust femtosecond pulses. These systems mix solid-state reliability with the performance perks of engineered saturable absorbers.

Modern active mode locking is way different from early setups. Back then, they used electro-optic or acousto-optic modulators in lamp-pumped Nd:YAG lasers. The basic modulation rules haven’t changed. But today’s systems use super-efficient diode-pumped designs—they’re more stable and reliable.

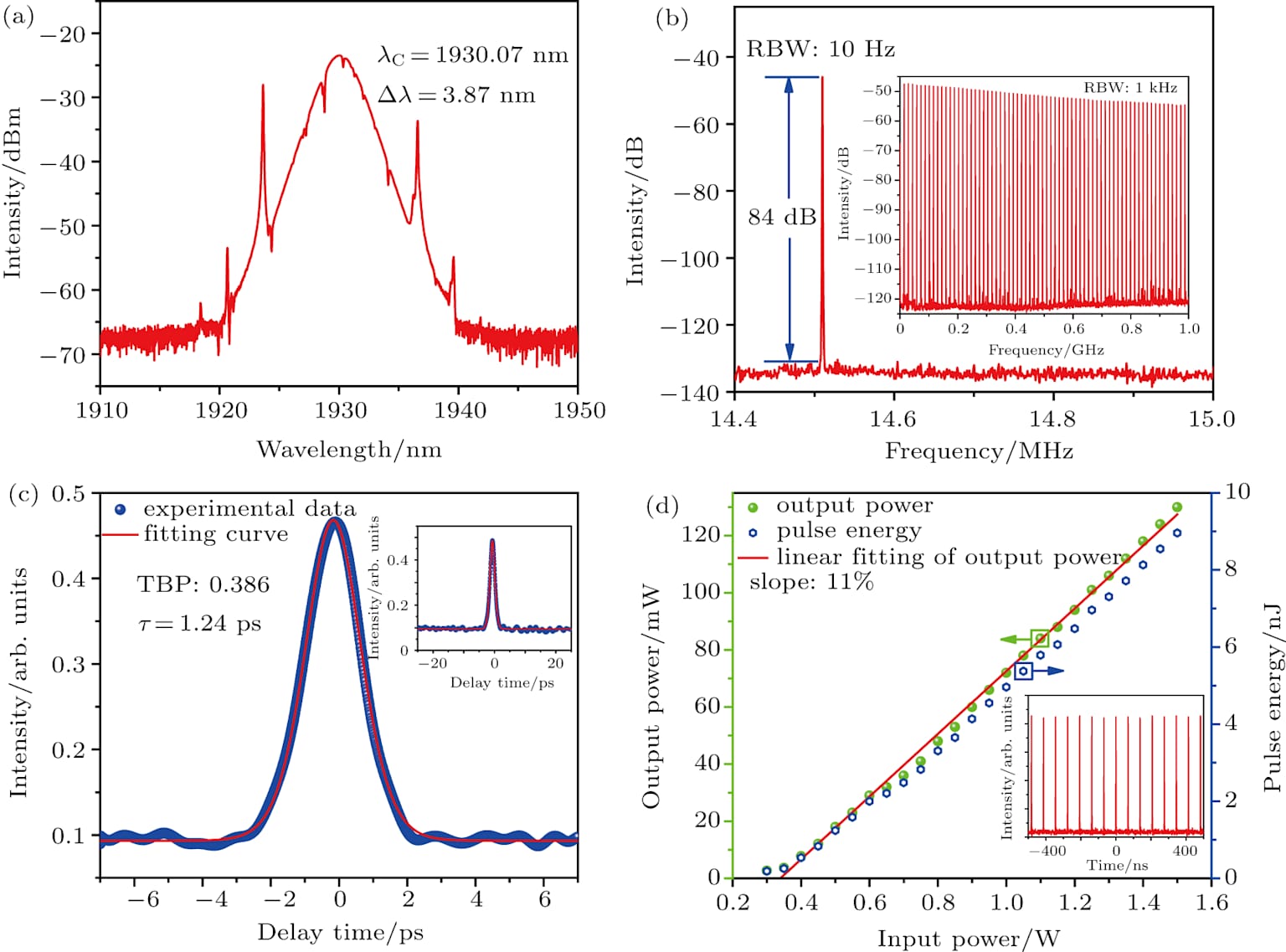

These advanced systems make super-stable mode-locked pulse trains. They’re perfect for seed pulses in high-power amplifiers. Today’s laser diode end-pumped Nd:YLF and Nd:YAG systems—actively mode-locked with acousto-optic modulators—regularly hit 10-20 picosecond pulses. They have amazing long-term energy stability and reproducibility. This mix of performance and reliability makes these systems a must for research and industry.

The global ultrafast laser market is booming. It went from $1.96 billion in 2023 to a projected $5.42 billion by 2030—that’s a 16.4% compound annual growth rate. Why? More demand for precision manufacturing. Ultrafast lasers let you do micromachining with almost no heat-affected zones.

Industrial uses cover lots of sectors—semiconductor processing, microelectronics manufacturing, precision cutting of advanced materials. The auto industry uses ultrafast lasers to make surface textures that boost engine efficiency. They also develop advanced exhaust gas sensors with them. These uses show how versatile ultrafast lasers are for solving tough manufacturing problems.

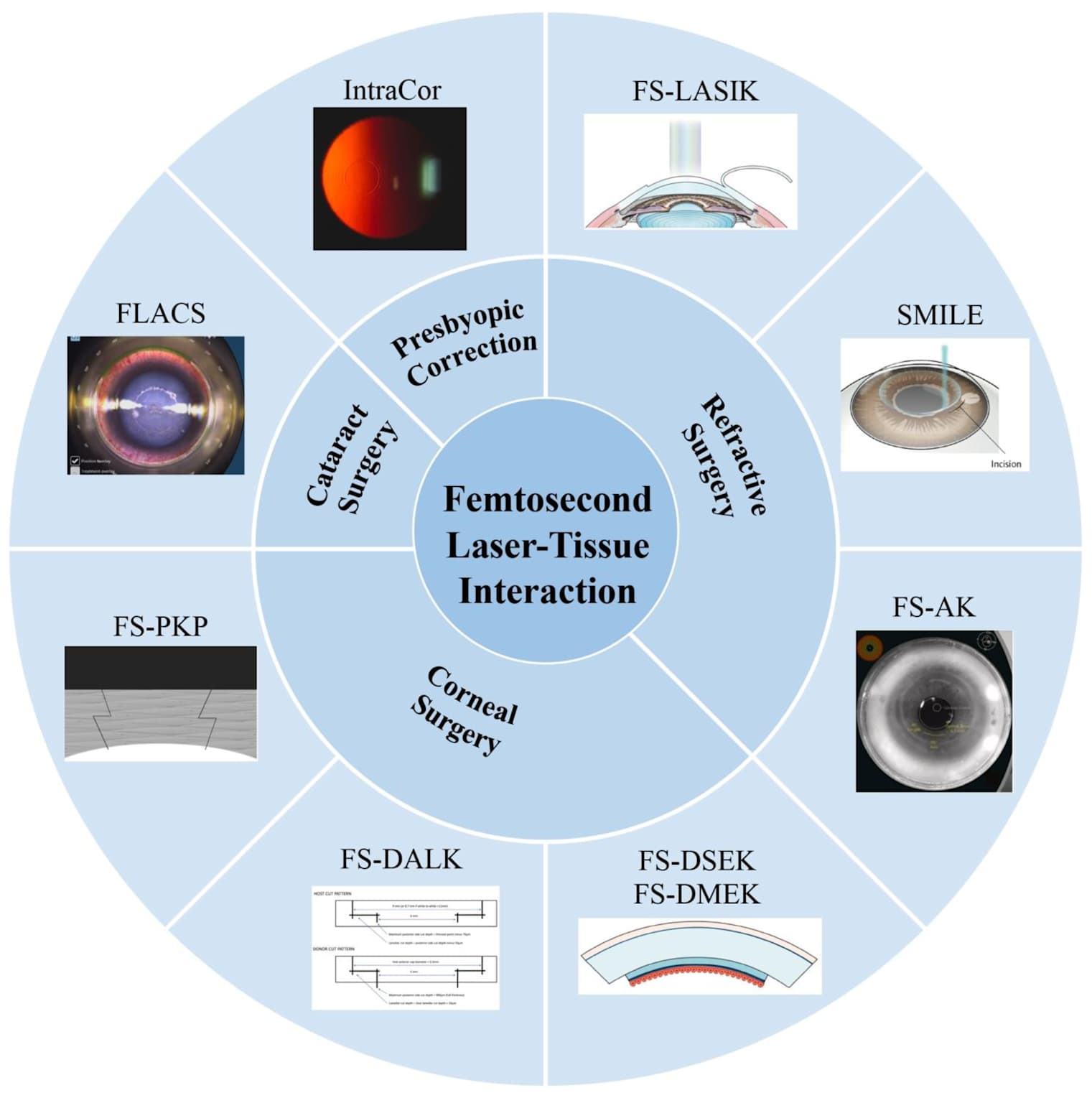

Medical and healthcare apps are the biggest market segment—about 35% of the global ultrafast laser market. Femtosecond lasers changed ophthalmic surgery forever. They let doctors do precision procedures like LASIK flap creation, cataract surgery, and corneal transplantation with never-before-seen accuracy.

The medical sector uses ultrafast lasers for more than just ophthalmology. They’re in dermatological treatments, biomedical imaging, and minimally invasive surgery. Being able to put energy exactly where you want—with femtosecond precision—while keeping thermal damage to surrounding tissues low has opened new doors in precision medicine.

Scientific research apps make up 20% of the market. They keep pushing ultrafast laser tech forward. These systems let scientists do time-resolved spectroscopy—capturing molecular dynamics on their natural timescales. This helps us understand fundamental physical and chemical processes better.

Quantum computing and precision measurement use ultrafast pulses’ unique time traits. They manipulate quantum systems and set up high-precision time standards with them.

The communications sector uses ultrafast lasers to make ultra-high-speed optical signals. This boosts data transmission capacity and speed a lot. Femtosecond and picosecond pulses let you use wavelength division multiplexing and time division multiplexing efficiently. This gets the most out of optical fiber infrastructure. This ability is getting more and more important as global data transmission demands keep growing exponentially.

Ultrrafast laser tech’s future is all about getting on mainstream manufacturing processes. Lower costs and better reliability are pushing this. Market forecasts say growth will stay strong through 2035. Apps will expand into smart manufacturing, advanced materials processing, and emerging quantum tech.

Tech developments are focusing on three things: better efficiency, simpler systems, and more wavelength coverage. This will meet diverse app needs. Adding AI and automated control systems will make ultrafast laser processes more precise and repeatable. That’ll make the tech easier to use for more industries.

Going from Q-switched nanosecond pulses to mode-locked femtosecond systems changed laser tech at its core. It made apps possible that were once out of reach because of time resolution limits. The journey from early organic dye systems to titanium-sapphire platforms to modern semiconductor-based designs shows how innovation never stops in this field.

Cavity design and pulse traits are still a core consideration. But mode locking fixed the cavity-length limits that held Q-switched systems back. Today’s setups let you control pulse duration like never before—using bandwidth engineering and advanced mode locking mechanisms.

As the tech gets more mature, the focus is shifting. Instead of just making shorter pulses, we’re optimizing system performance for specific apps. And we’re keeping costs low and reliability high. The big market growth and wide range of apps show that ultrafast lasers will keep playing a bigger role in research, medicine, and precision manufacturing.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China