Laser marking technology has revolutionized industrial manufacturing and product identification, but it raises important questions about human health and safety. Understanding the potential effects of laser marking on the human body is crucial for establishing proper safety protocols and protecting workers in environments where these powerful tools are used.

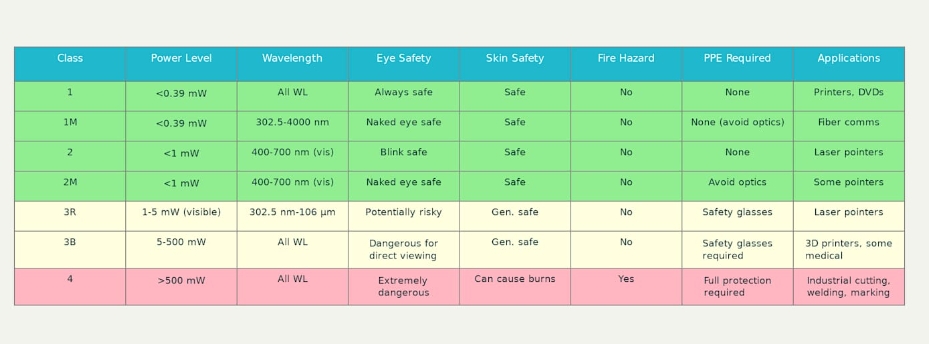

The International Electrotechnical Commission (IEC) has established a comprehensive classification system under IEC 60825-1 standards to categorize lasers based on their potential hazards to human health. This system divides lasers into distinct classes, each with specific safety requirements and risk levels .

Class 1 Lasers: Maximum Safety

Class 1 lasers represent the safest category in the classification system . These devices operate with power levels below 0.39 milliwatts and are considered safe under all normal operating conditions . The laser radiation in Class 1 systems remains well below hazardous levels, making them suitable for everyday consumer applications . Common examples include laser printers and DVD players, where the laser beam is completely enclosed within the device .

Class 1M lasers emit radiation with wavelengths between 302.5 nm and 4,000 nm. While generally safe for direct viewing with the naked eye, these lasers can become hazardous when viewed through optical instruments such as telescopes or microscopes . The "M" designation indicates that magnifying optics increase the potential danger from these otherwise safe laser systems.

Class 2 lasers emit visible radiation between 400 nm and 700 nm wavelengths . These systems rely on the human eye's natural protective mechanisms, including the blink reflex, which typically limits exposure to 0.25 seconds or less . This natural aversion response to bright light provides adequate protection under normal circumstances. Class 2M lasers share similar characteristics but pose additional risks when used with optical instruments.

Class 3R lasers represent an intermediate risk category with power outputs between 1-5 milliwatts for visible wavelengths . Direct viewing of the beam is potentially dangerous, though the risk level remains lower than Class 3B lasers . These systems require safety glasses as a recommended precaution, and the accessible emission limits are within five times the Class 2 limit for visible wavelengths .

Class 3B lasers pose significant dangers for direct beam exposure, with power levels ranging from 5-500 milliwatts . These systems are hazardous within the Nominal Ocular Hazard Distance (NOHD), though diffuse reflections are generally considered safe. Safety glasses become mandatory equipment when working with Class 3B lasers .

Class 4 lasers represent the highest hazard classification, with power outputs exceeding 500 milliwatts. These systems can cause severe eye injuries, skin burns, and fire hazards. Both direct beam exposure and diffuse reflections pose significant dangers to operators and bystanders. Class 4 lasers require comprehensive safety measures including protective equipment, engineering controls, and administrative procedures .

Laser radiation affects different parts of the human body in various ways, depending on wavelength, power level, and exposure duration. Understanding these effects is essential for implementing appropriate safety measures and protective protocols.

The human eye represents the most vulnerable target for laser radiation exposure. Different wavelengths affect various parts of the eye structure, with the retina being particularly susceptible to wavelengths between 400-1400 nm. These wavelengths can penetrate the eye and focus on the retina, potentially causing thermal burns and permanent vision loss.

Corneal damage typically occurs from ultraviolet radiation between 180-400 nm, resulting in photokeratitis and potential cataract formation. The lens of the eye can develop cataracts when exposed to radiation in the 400-1400 nm range, often resulting in permanent damage. Retinal injuries from laser exposure are frequently irreversible and can lead to complete blindness in severe cases.

Laser radiation can cause various types of skin damage, from mild erythema to severe burns requiring medical treatme. The epidermis is most susceptible to ultraviolet radiation and infrared wavelengths above 1400 nm, typically resulting in surface burns that heal within days to weeks. Deeper dermal injuries occur with wavelengths between 400-1400 nm, potentially causing scarring and requiring weeks to months for recovery.

The thermal effects of laser radiation depend on several factors including wavelength, power density, and exposure duration. High-powered Class 4 lasers can cause immediate skin burns and may ignite clothing or other flammable materials.

Laser marking and cutting operations can generate hazardous fumes and particles that pose respiratory health risks. These airborne contaminants may contain toxic chemicals and metal particles that can cause immediate irritation and long-term health problems. Proper ventilation systems and respiratory protection become essential when working with materials that generate harmful fumes during laser processing.

Modern laser safety relies heavily on engineering controls that provide the highest level of protection for operators and bystanders. These systems are designed to eliminate or significantly reduce laser hazards through physical barriers and automated safety mechanisms.

Complete laser enclosures represent the most effective engineering control for high-powered laser systems. These enclosures prevent laser radiation from escaping the work area and automatically shut down the laser when opened. Safety interlocks serve as critical backup systems, ensuring that lasers cannot operate when protective barriers are compromised.

Proper ventilation systems are essential for removing hazardous fumes and particles generated during laser marking operations. Local exhaust ventilation (LEV) systems capture contaminants at the source, preventing their dispersion into the work environment. These systems must be designed specifically for the materials being processed and the types of fumes generated.

Personal protective equipment serves as the final line of defense against laser hazards, particularly for Class 3B and Class 4 systems. Proper selection and use of PPE is critical for preventing injuries during laser operations.

Laser safety glasses represent the most important piece of personal protective equipment for laser operators. These specialized glasses must be selected based on the specific wavelength and power level of the laser being used. The optical density rating of safety glasses must provide sufficient protection to reduce laser power to safe levels.

Different laser wavelengths require different lens materials and coatings to provide adequate protection . Visible light transmission requirements must be balanced with protection levels to ensure operators can perform their tasks safely and effectively. Regular inspection and replacement of laser safety glasses is essential to maintain their protective capabilities.

Class 4 laser operations may require additional protective equipment beyond safety glasses. Flame-resistant clothing helps protect against burns and fire hazards associated with high-powered lasers. Respiratory protection becomes necessary when laser operations generate hazardous fumes or particles.

Administrative controls complement engineering controls and PPE to create comprehensive laser safety programs. These measures focus on human factors and organizational procedures that reduce laser hazards through proper training and work practices.

Comprehensive training programs are essential for all personnel working with or around laser systems. Training must cover laser hazards, safety procedures, emergency response, and proper use of protective equipment. Only qualified and trained operators should be permitted to use laser marking equipment.

Controlled access to laser work areas helps prevent unauthorized exposure to laser hazards. Warning signs and labels must be posted at all entry points to laser-controlled areas. These signs should clearly indicate the laser class, wavelength, and required safety precautions .

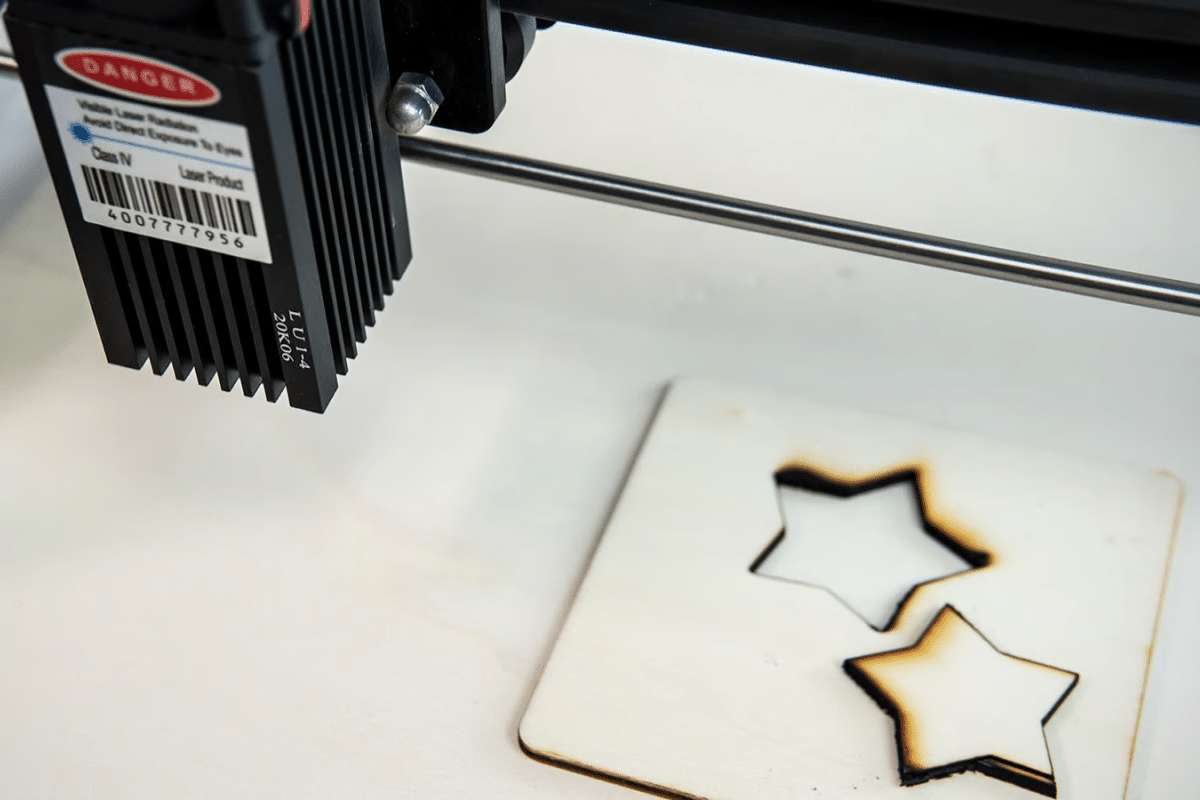

CO2 laser markers (ML-G series) and YAG laser markers (MD-H series) are classified as Class 4 lasers, representing the highest hazard category in the laser safety classification system. These industrial laser marking systems require the most stringent safety measures due to their high power output and multiple hazard types.

Class 4 laser marking systems pose multiple hazards beyond simple beam exposure. These systems can cause severe eye injuries including permanent blindness from both direct and reflected beam exposure . Skin burns can occur from direct contact with the laser beam, and fire hazards exist due to the high power output capability .

The invisible nature of many Class 4 laser wavelengths adds additional complexity to safety considerations. CO2 lasers typically operate at 10.6 micrometers in the infrared spectrum, making the beam invisible to the human eye. This invisibility increases the risk of accidental exposure since operators cannot visually track the beam path.

Operating Class 4 laser marking systems requires implementation of multiple safety control measures simultaneously. Engineering controls must include complete beam enclosures or controlled access areas with safety interlocks. Administrative controls including comprehensive training, written procedures, and designated laser safety officers become mandatory.

Personal protective equipment requirements for Class 4 systems are extensive and must be carefully matched to the specific laser parameters. Laser safety glasses must provide adequate optical density for the wavelength and power level in use. Additional protective equipment may include flame-resistant clothing and respiratory protection depending on the materials being processed.

Implementing effective laser marking safety requires a systematic approach that addresses all aspects of laser hazards and protective measures. Organizations must develop comprehensive safety programs that integrate engineering controls, administrative procedures, and personal protective equipment into cohesive safety management systems.

Periodic hazard assessments help identify potential safety issues and ensure that protective measures remain effective. These assessments should evaluate all laser systems, safety equipment, and work procedures to verify compliance with current safety standards. Regular maintenance of safety equipment and systems is essential for maintaining their protective capabilities.

Comprehensive emergency response procedures must be established for laser incidents including eye exposure, skin burns, and fire emergencies. All personnel working with laser systems should be trained in emergency response procedures and know how to access medical care quickly. Emergency contact information and incident reporting procedures should be readily available in all laser work areas.

Laser safety in the workplace is governed by multiple regulatory frameworks and industry standards that establish minimum safety requirements . In the United States, the Occupational Safety and Health Administration (OSHA) adopts ANSI Z136 series standards as the regulatory framework for workplace laser safety .

The ANSI Z136.1 standard provides comprehensive guidance for the safe use of lasers in industrial applications. Recent updates to the ANSI Z136.3 standard for healthcare applications demonstrate the ongoing evolution of laser safety requirements. International standards such as IEC 60825 provide globally consistent approaches to laser safety .

Laser marking systems, particularly CO2 and YAG laser markers classified as Class 4 devices, can have significant effects on human health if not properly controlled. The comprehensive classification system established by IEC standards provides a framework for understanding laser hazards and implementing appropriate safety measures.

The potential health effects range from minor skin irritation to permanent blindness and severe burns, making proper safety protocols absolutely essential. Engineering controls such as enclosures and interlocks provide the highest level of protection, while administrative controls and personal protective equipment serve as additional layers of safety.

Success in laser marking safety requires a commitment to comprehensive safety programs that address all aspects of laser hazards. Regular training, proper equipment maintenance, and adherence to established safety standards help ensure that laser marking operations can be conducted safely and effectively. When properly implemented, these safety measures allow organizations to harness the benefits of laser marking technology while protecting workers from potential health hazards.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China