End-pumped laser systems are an sophisticated optical pumping method. They’ve revolutionized solid-state laser design with better efficiency and beam quality. Unlike transverse pumping, this longitudinal method injects pump light on the laser beam axis. It creates exceptional spatial overlap between pump radiation and laser modes. Today, it’s the foundation for most modern diode-pumped solid-state lasers. It’s especially useful in applications needing high efficiency and diffraction-limited beam quality.

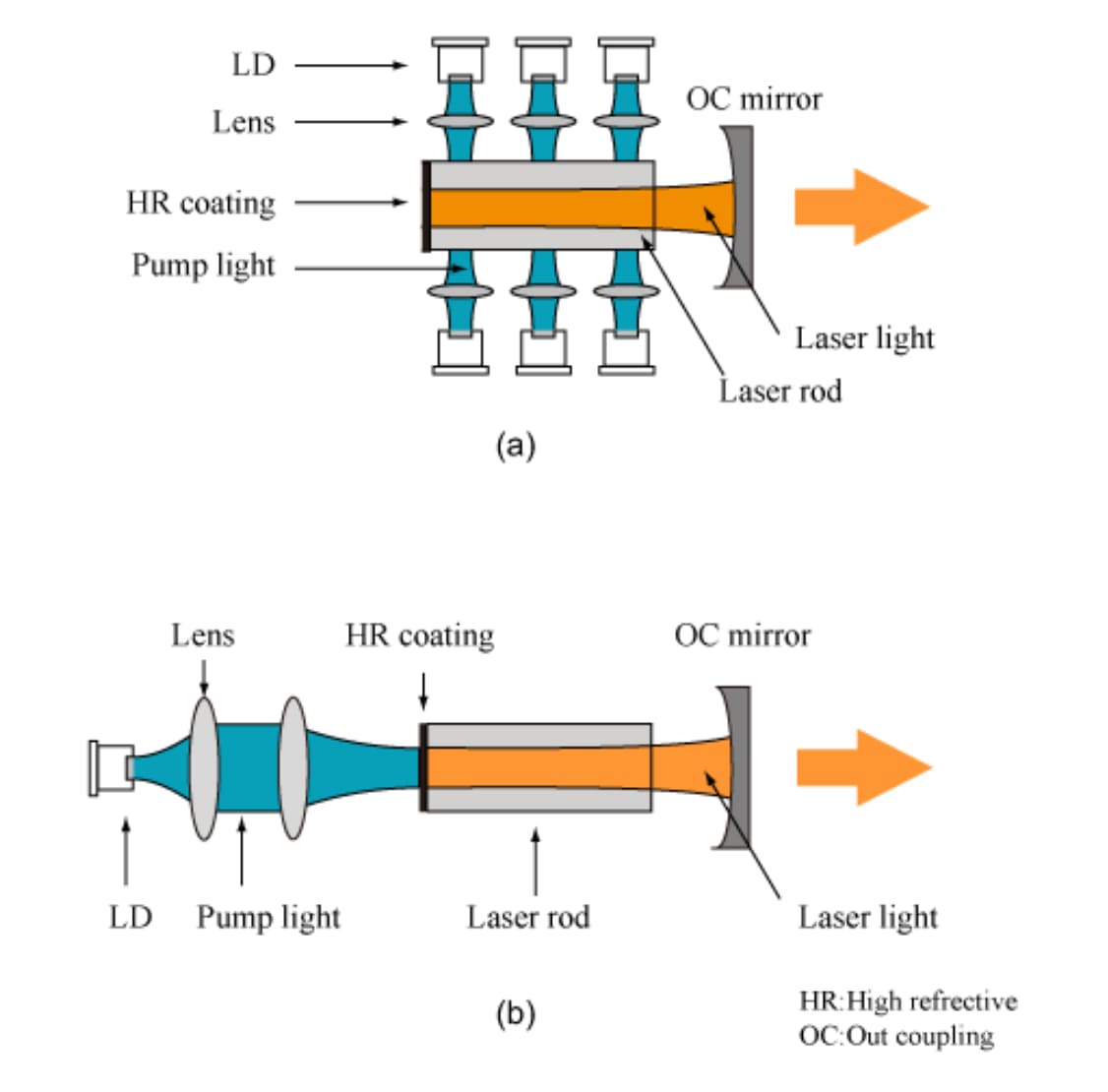

End-pumping differs from side-pumping in its axial injection design. Pump light travels straight along the laser resonator mode. This design creates optimal spatial overlap between excited ion distribution and fundamental laser mode. It boosts gain extraction efficiency. Pump beam usually enters through one end of the laser crystal. Absorption happens on the path, following Beer's law. This geometric setup lets you precisely control on the pumped volume. You can selectively excite only regions that help laser oscillation. This spatial selectivity sets end-pumping apart from side-pumping. In side-pumping, pump light often spreads over the useful laser mode volume. Longitudinal design also makes bidirectional pumping possible. You can inject pump light from both crystal ends for more uniform excitation.

End-pumped systems succeed because they achieve optimal spatial overlap between pump and laser modes. If pump beam diameter matches the fundamental transverse mode diameter, higher-order modes don’t get enough gain to reach laser threshold. This natural mode discrimination lets you operate in single mode without extra intracavity apertures. Pump sources for end-pumped systems need much better beam quality than those for side-pumped setups. You usually need high-brightness diode lasers or fiber-coupled systems to get the right pump beam quality. Pump beam must stay focused over the entire crystal length. This is especially true for long gain media where absorption happens slowly.

End-pumped systems are more power-efficient than side-pumped ones. They use pump radiation more effectively. End-pumped systems have electrical-to-optical conversion efficiencies of 15-25%. That’s much higher than the 8-15% of side-pumped setups. This improvement comes from less pump light wasted in regions that don’t help laser oscillation. Better efficiency comes from precise spatial matching between pump distribution and laser mode profile. Side-pumping absorbs a lot of pump power in regions outside the laser mode. End-pumping concentrates excitation in the useful gain volume. This targeted pumping reduces thermal loading while maximizing laser output.

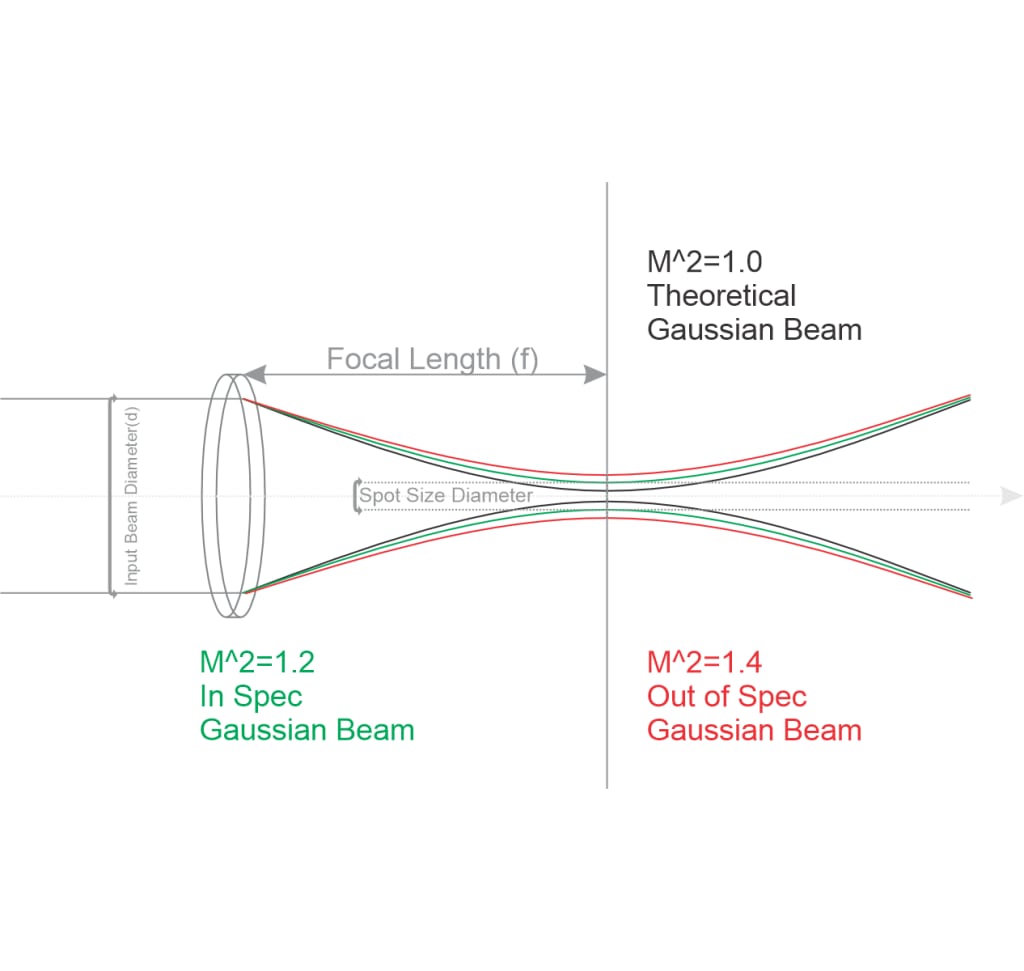

Single-mode operation with near-diffraction-limited beam quality is an key advantage of end-pumped systems. Spatial overlap between pump and fundamental mode creates a soft aperture effect. It blocks higher-order modes. Well-designed end-pumped lasers usually have beam quality factors (M²) of 1.1-1.5. To get excellent beam quality, you need to pay close attention to pump beam size relative to the fundamental mode. Optimal performance happens when laser mode radius is slightly smaller than pump intensity distribution radius. This relationship stops thermal lensing from degrading the laser mode. It also keeps pump absorption sufficient.

End-pumped systems have inherent limits on pump power delivery because of their design. You can only inject pump light from two crystal faces at most. This limits the total pump power you can use. This restriction is a big problem for high-power applications. Side-pumping is better for scaling power in these cases. Needing high-quality pump sources also limits how much you can scale power. Long laser crystals with small beam diameters need pump sources with exceptional brightness. Standard diode bars often can’t meet this. So lamp-pumped lasers usually can’t be end-pumped. Their beam quality is too poor.

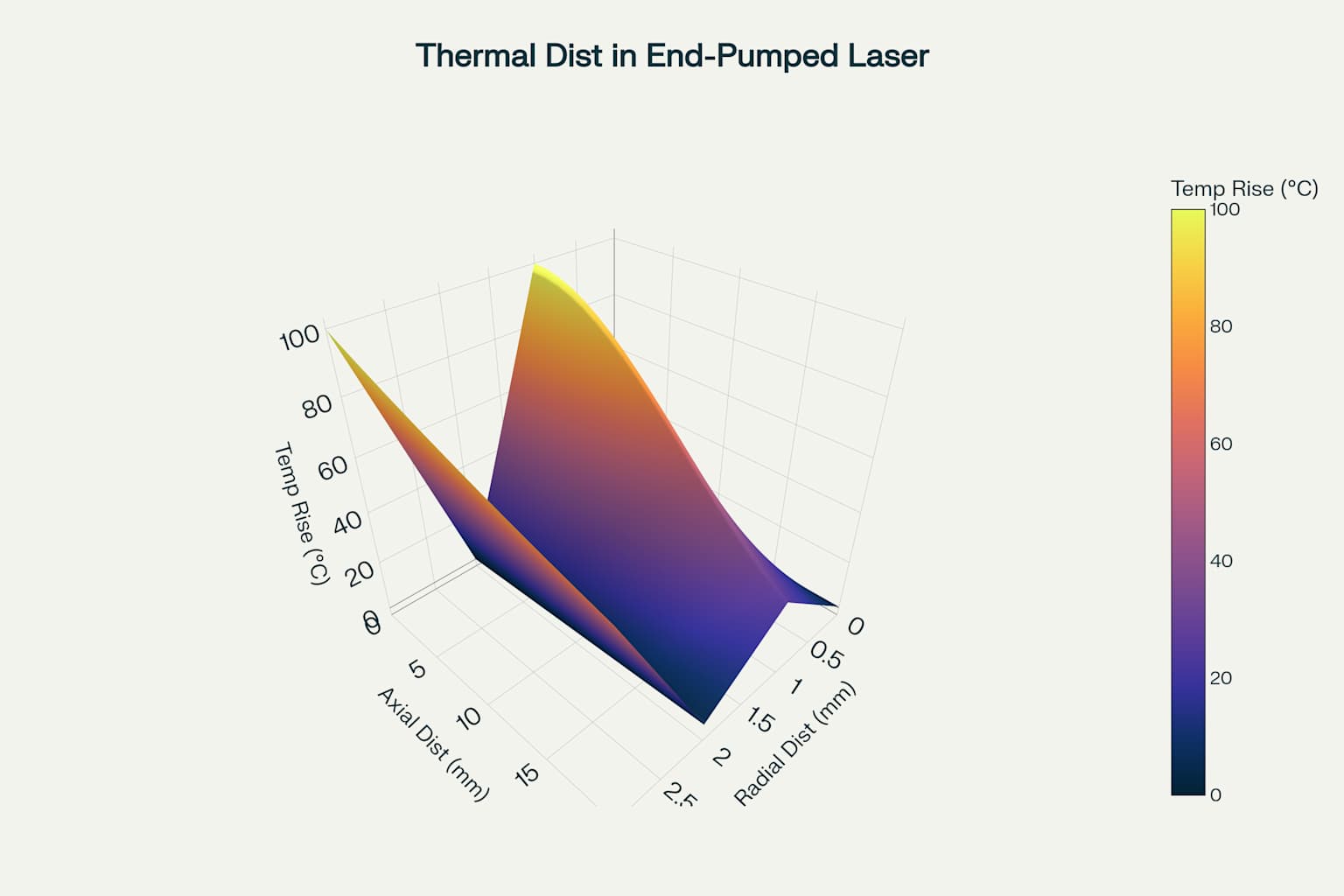

Thermal effects are the main limit for scaling power in end-pumped systems. Localized heat from pump absorption creates big temperature gradients and thermal lensing. These thermal distortions can ruin beam quality. They might even break the crystal at high power. Thermal distribution in end-pumped crystals is very uneven. Peak temperatures are at the pump entry point. This localized heating creates complex thermal lens effects. These effects change with pump power and can make the laser unstable. You need advanced thermal management techniques to scale power. These include better cooling and optimized crystal geometry.

Axial temperature variation in end-pumped crystals follows the pump absorption profile. It creates radial and longitudinal thermal gradients. These temperature changes make the refractive index change. This acts as a thermal lens and affects laser mode propagation. Thermal lens power goes up with pump power. This might cause resonator instability. Bidirectional pumping can reduce thermal gradient effects a lot. It distributes heat more evenly along the crystal length. But this approach needs two pump sources. It also needs more complex optical setups. Other solutions include composite crystal designs and advanced cooling.

Composite laser crystals are an promising way to extend end-pumping to higher power. They combine doped and undoped crystal sections. This improves thermal management and power handling. Undoped end caps add extra heat conduction paths. They also keep the benefits of end-pumping design. Experiments show big performance improvements with composite crystals. These include less thermal lensing and better power scaling. Optimal design balances thermal management benefits with possible optical losses at bonded interfaces. Advanced bonding techniques keep optical distortion low. They also maintain mechanical integrity.

Fiber-coupled pump systems let you deliver pump light flexibly for end-pumped lasers. They combine multiple diode sources using fiber bundling. This achieves high pump power while keeping beam quality good. Fiber coupling also does spatial filtering. This improves pump beam quality. High-brightness fiber-coupled systems can deliver hundreds of watts of pump power. They use relatively small fiber cores. This lets you scale power in end-pumped systems. You still keep the geometric advantages of longitudinal pumping. Fiber coupling also makes thermal management easier. It separates pump source heat from the laser crystal.

End-pumped lasers are widely used in scientific applications. These applications need high beam quality and stable operation. They have excellent beam quality, high efficiency, and stable operation. This makes them ideal for spectroscopy, interferometry, and precision measurement. Single-mode operation is especially valuable for applications needing coherent light sources. Medical and industrial applications also benefit from end-pumped systems’ superior beam quality. They can focus tightly and control beams precisely. This enables use in laser surgery, materials processing, and optical communications. They’re compact and efficient. This makes them attractive for portable and battery-operated applications.

Most commercial diode-pumped solid-state lasers under 10 watts use end-pumping. This technology has made compact, efficient laser systems possible. They’re used in many applications. Wavelength conversion using nonlinear processes benefits a lot from end-pumped systems’ high beam quality. Diode-pumped end-pumped systems are reliable and last long. This makes them attractive for industrial use. They don’t have consumable components like flashlamps. This reduces maintenance and operating costs. This reliability has made them widely adopted in manufacturing and processing.

Researchers are working on better thermal management techniques for end-pumped systems. New cooling methods like micro-channel cooling and cryogenic operation show promise for scaling power. Advanced crystal materials with better thermal properties also help improve performance. Thermal lens compensation techniques using adaptive optics or designed elements can reduce thermal effects. These methods let you operate at higher pump powers. You still keep beam quality good. Adding real-time thermal monitoring and control systems makes systems more stable.

New pump configurations like shaped beam pumping and multi-wavelength pumping offer new ways to improve performance. They can improve pump absorption efficiency. They also reduce thermal loading. New pump diode technologies with better brightness and efficiency are being developed. They keep expanding what end-pumped systems can do. Coherent beam combining techniques for pump sources let you scale to higher powers. You still meet beam quality requirements. They could let end-pumping reach power levels that only side-pumping could before. Adding advanced beam shaping and control techniques will likely improve performance more.

End-pumped laser technology is a mature, successful way to design solid-state lasers. It’s more efficient and has better beam quality than other pumping methods. Its fundamental advantages—spatial overlap and selective excitation—make it the top choice for applications needing high-quality laser output. Thermal management challenges limit how much you can scale power. But advanced techniques like composite crystals and better cooling keep extending what end-pumped systems can do. Its impact on scientific, industrial, and commercial applications shows how important it is in modern laser technology. Continuing to develop thermal management, pump sources, and crystal engineering will likely make end-pumped systems better. As applications need higher performance and reliability, end-pumped laser technology will stay key to meeting these needs.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China