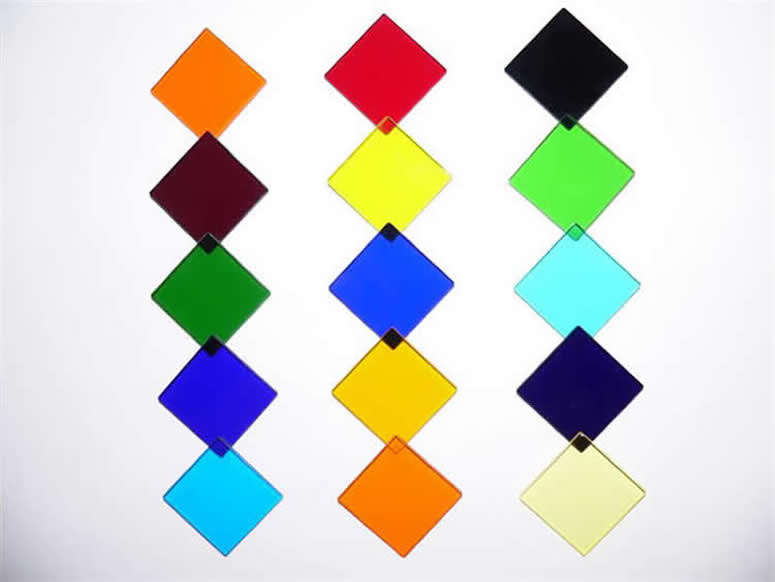

Colored optical filter glass is an specialized category of optical materials. It manipulates electromagnetic radiation selectively, via controlled absorption, transmission, and filtering mechanisms. These materials act as fundamental components on numerous technological applications — from precision spectroscopic instrumentation to advanced photonic systems. Specific wavelength control matters for optimal performance here. Sophisticated nomenclatural systems for these materials let manufacturers, researchers, & end - users communicate precisely across international markets & applications.

Colored optical filter glass materials gain essential spectral control capabilities through multiple operational modes. These include selective wavelength cutoff, bandpass transmission, infrared transparency, and ultraviolet blocking functions. These specialized glasses enable precise color filtering, chromatic correction, optical separation, and spectral compensation. They’re used on scientific instrumentation, photography, astronomy, and industrial measurement systems. The selective absorption characteristics of these materials come from carefully controlled chemical compositions and manufacturing processes. These determine their specific transmission and absorption profiles.

Modern filter glasses play critical roles in fluorescence microscopy, Raman spectroscopy, and various analytical instrumentation. Precise wavelength discrimination is needed for accurate measurements and signal processing here. The term “filter glass” reflects the primary function of these materials: selectively transmit desired wavelengths while absorbing or reflecting unwanted spectral components.

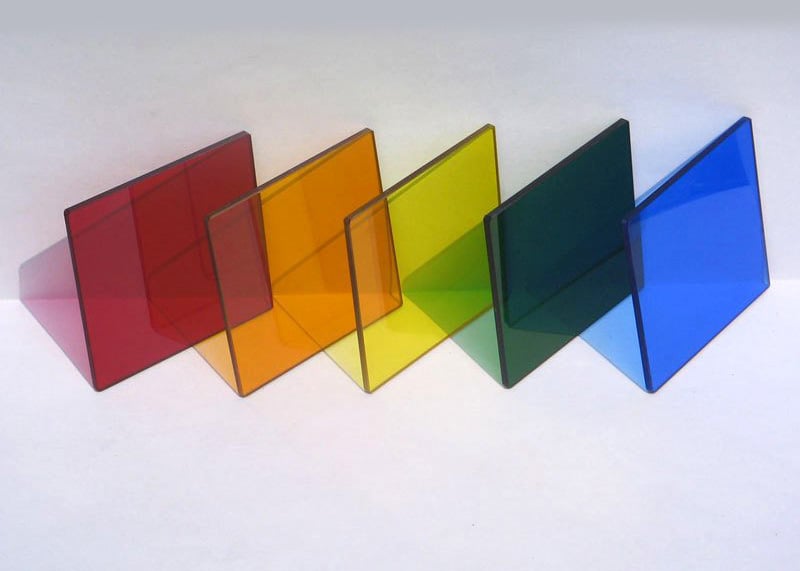

The optical performance of colored filter glass is fundamentally characterized by its wavelength - dependent transmission properties. These determine the specific spectral regions that can pass through the material with minimal attenuation. These transmission characteristics are usually quantified through detailed spectroscopic analysis. It measures internal transmittance across the electromagnetic spectrum — from ultraviolet through visible to near - infrared regions. The absorption and transmission profiles of filter glasses relate directly to their chemical composition. Especially the presence of specific chromophoric ions and matrix modifications.

The international optical industry uses an standardized nomenclatural system for colored filter glasses. It’s based mainly on their spectral characteristics and intended applications. Ultraviolet - transmitting glasses named “UG” provide selective transmission in the ultraviolet region. They look black or blue under visible inspection and work as effective bandpass filters for spectroscopic applications. Blue and teal glasses classified as “BG” offer multi - band transmission characteristics. They’re optimized for microscopy, analytical instrumentation, and specialized lighting applications.

Green filter glasses named “VG” provide selective transmission in the green part of the visible spectrum. They’re widely used on measurement instruments, observation devices, and precision rangefinding systems. The “GG” classification includes glasses from colorless to yellow appearances. They maintain high infrared transmission, making them valuable for night vision applications and thermal imaging systems.

Orange glasses named “OG” combine visible orange coloration with infrared transparency. They’re quite useful on photography and specialized imaging applications. Red and near - infrared transmitting glasses classified as “RG” range from red through black appearances. They maintain infrared transmission capabilities essential for long - distance photography and specialized optical systems.

Neutral density glasses named “NG” provide wavelength - independent attenuation across broad spectral ranges. They offer uniform transmission reduction without selective color effects. These filters are essential for applications needing light intensity control without spectral distortion. This includes observation instruments, photographic exposure control, and laser power management systems.

The environmentally friendly “N - WG” classification stands for colorless glasses with ultraviolet absorption bands. They maintain high transmission in visible and infrared regions. The “N - ” prefix specifically shows compliance with environmental regulations. This is done by eliminating lead and arsenic components, reflecting the industry’s shift toward sustainable optical materials.

Heat - absorbing glasses named “KG” act as shortpass filters. They transmit visible wavelengths while absorbing infrared radiation. They provide essential thermal protection on high - intensity lighting and laser applications.

Matrix glass is the fundamental category. Optical absorption happens through intrinsic properties of the base glass composition — without adding visible - range chromophores. These materials, like N - WG glasses, achieve ultraviolet absorption through matrix - inherent characteristics. They stay colorless and transparent in the visible spectrum. The absorption mechanisms in matrix glasses come from electronic transitions within the base glass network structure — not from discrete chromophoric centers.

Manufacturing matrix glasses needs precise control of base glass composition. This is to achieve desired ultraviolet cutoff characteristics without adding visible coloration. These materials offer excellent optical homogeneity and thermal stability. They also meet environmental compliance requirements.

Ionic tinted glasses get their optical properties by incorporating chromogenic heavy metal ions or rare earth elements. These provide specific electronic absorption transitions. The coloration and spectral characteristics of these glasses depend heavily on multiple factors. These include the specific ionic species, dopant concentration, oxidation state, and interaction with the host glass matrix.

Transition metal ions like chromium (Cr³⁺), cobalt (Co²⁺), copper (Cu²⁺), and iron (Fe²⁺/Fe³⁺) give characteristic colors through d - electron transitions. These can be precisely controlled through glass composition and processing conditions. Rare earth ions including neodymium (Nd³⁺), praseodymium (Pr³⁺), and erbium (Er³⁺) offer unique spectroscopic properties. These are valuable for laser applications and specialized optical systems.

Colloidal tinted glasses are the most sophisticated category. Coloration forms through controlled precipitation of metallic nanoparticles during post - formation heat treatment processes. These materials are colorless right after initial cooling from the melt. But they develop intense coloration when exposed to specific thermal treatment protocols that promote nanoparticle nucleation and growth.

The optical properties of colloidal glasses come from surface plasmon resonance effects in metal nanoparticles. This produces characteristic steep absorption edges. Their position depends on particle size, composition, and concentration. Silver, copper, and gold nanoparticles create different coloration effects. Precise control is achieved by carefully managing heat treatment temperature, time, and atmospheric conditions.

Chinese optical glass standards use an systematic alphanumeric nomenclature. English letters show glass characteristics and the suffix “B” denotes glass material. This classification system lets filter glass properties be specified precisely. It also maintains compatibility with international optical design software and manufacturing requirements. Infrared - transmitting glasses named “HWB” serve night vision and thermal imaging applications. Yellow glasses marked “JB” support photographic and imaging systems that need selective color transmission.

Neutral density glasses identified as “AB” provide broadband attenuation. They’re for observation instruments and optical measurement systems that need controlled light levels. The systematic grade numbering in each category allows precise specification of transmission characteristics and optical performance parameters.

Chinese standards recognize eleven distinct categories of colored optical glass. Each is optimized for specific application domains and performance requirements. Ultraviolet - transparent glasses named ZWB support spectroscopic instrumentation and specialized illumination systems that need UV transmission. Blue and cyan glasses (QB series) serve microscopy and analytical applications where blue wavelength transmission is critical.

Green glasses (LB series) provide essential components for measurement instruments, observation systems, and precision rangefinding equipment. Green wavelength selectivity boosts performance here. Protective glasses (FB series) offer essential eye and sensor protection on industrial and military applications.

Contemporary optical glass manufacturing has moved toward environmentally compliant formulations. These eliminate toxic heavy metals while keeping superior optical performance. Lead - free and arsenic - free glasses now are the standard for new optical systems. This is driven by regulatory requirements like the European Union's RoHS directive and similar international standards. These eco - friendly formulations achieve equivalent optical properties through innovative rare earth dopants and advanced glass matrix compositions.

Environmental compliance goes beyond eliminating toxic elements. It includes considering energy consumption during manufacturing, recyclability of finished products, and reducing greenhouse gas emissions. Modern processing techniques let high - performance optical glasses be produced at reduced temperatures. This contributes to overall sustainability goals.

Modern optical filter glass production uses sophisticated manufacturing processes. These include precision melting, controlled cooling, and advanced quality control systems. They ensure consistent optical properties. Ion - assisted deposition techniques and advanced coating technologies let complex spectral responses be created — ones that go beyond the capabilities of traditional bulk glass coloration methods.

Automated production systems with real - time spectroscopic monitoring ensure precise control of glass composition and optical properties during the manufacturing process. These technological advances let custom filter glasses with tailored spectral characteristics be produced for specialized applications.

Optical filter glass quality is governed by comprehensive international standards. These include ISO 12123 for raw optical glass specification and ISO 8424 for chemical resistance testing. These standards set up protocols for optical property measurement, dimensional tolerances, and environmental resistance characteristics. These are essential for reliable optical system performance.

Testing methodologies include precision spectrophotometry for transmission measurement, chemical durability assessment through controlled exposure protocols, and mechanical property evaluation under standardized conditions. Modern quality control systems use automated spectroscopic analysis to check compliance with specified optical characteristics.

Contemporary optical glass characterization uses multiple analytical techniques. These include Raman spectroscopy, X - ray photoelectron spectroscopy, and nuclear magnetic resonance. They help understand structural relationships between composition and optical properties. These sophisticated analytical methods let glass formulations be optimized for specific applications while ensuring consistent manufacturing quality.

Visible light transmission measurements using calibrated instruments give quantitative assessment of filter performance across intended spectral ranges. Advanced characterization protocols include temperature - dependent measurements and long - term stability testing. These ensure reliable performance in demanding applications.

The systematic nomenclature and classification of colored optical filter glass is a critical foundation for modern photonic technology development and optical system design. International standardization efforts have created comprehensive frameworks. They let material specifications be communicated precisely while supporting innovation in sustainable glass formulations. The shift from traditional lead - based glasses to environmentally compliant alternatives shows the industry's commitment. It combines superior optical performance with responsible manufacturing practices.

Advanced manufacturing technologies and sophisticated characterization methods keep expanding the capabilities of colored optical glass materials. They enable new applications in emerging fields like quantum photonics, advanced sensing systems, and next - generation optical communications. The comprehensive classification systems established by international standards organizations provide the necessary framework for continued innovation. They also ensure reliable performance across diverse applications and markets.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China