Ultraviolet (UV Lasers)—laser sources emitting electromagnetic radiation in 10 nm to 400 nm—hold an unique spot on photonics. Their short wavelengths let them achieve unmatched spatial resolution, strong photon-matter coupling, and “cold” material processing—yet they face big design an lifetime challenges. This article looks at key physics, device designs, and industrial uses of UV Lasers—plus recent advances expanding their use.

UV spans three practical regions: near-UV (300–400 nm), deep-UV (200–300 nm), an extreme-UV (< 200 nm). Shorter wavelengths mean higher photon energy (E = hc/λ)—so UV photons pack more punch for processes like photopolymerization an bond breaking. But they also scatter more in air an get absorbed by most materials—making beam delivery tricky.

Material degradation: UV photons break chemical bonds in optics, causing “solarization” (loss of transmission) over time.

Thermal effects: High photon energy leads to more heat in gain media—reducing efficiency an lifetime.

Phase matching: Nonlinear frequency conversion (needed for many UV sources) requires precise alignment of crystal axes an beam parameters.

Excimer lasers (e.g., KrF at 248 nm, ArF at 193 nm) are gas lasers using excited dimers—they’re popular for industrial machining because of high average power (up to 100 W) an short pulses (1–50 ns). But they need frequent gas refills an have short lifetimes (1–5 billion pulses).

Solid-state lasers (e.g., Nd:YAG, Yb:YAG) use crystal or glass gain media—they’re stable an reliable, but need frequency conversion to reach UV. For example, one compact deep-UV CW laser hits over 0.5 W at 261 nm—good for spectroscopies.

Nd-doped ZBLAN or fluoride fibers lase near 380 nm, but they only reach a few kW average power—plus they’re stuck on large facilities because of accelerator size an cost.

Representative UV output wavelengths across these laser types are visualized below.

| Fundamental | SHG (λ/2) | THG (λ/3) | FHG (λ/4) | Common Crystal Setup | Everyday Use |

|---|---|---|---|---|---|

| 1064 nm Nd:YAG | 532 nm | 355 nm | 266 nm | LBO → LBO/BBO | PCB drilling, LIBS |

| 1030 nm Yb:YAG | 515 nm | 343 nm | 257 nm | LBO → CLBO | EUV pump, semiconductor metrology |

Fifth-harmonic generation (213 nm) an sum-frequency mixing extend access to 200–230 nm lines, but crystal degradation an phase-matching bandwidth narrow quickly.

External-cavity GaAs diodes or VECSELs—doubled resonantly twice—make 280–390 nm tunable CW light over 100 mW in small package.

Substrate choices: UV-grade fused silica (down to 193 nm), CaF₂ (to 180 nm), sapphire (to 150 nm) mix transmission, birefringence, an hardness well.

Coatings: Al + MgF₂ mirrors work for 200–400 nm; multilayer fluoride stacks for DUV need super tight λ/20 thickness tolerance.

Beam delivery: Solarization-resistant silica or hollow-core fibers carry 10–100 mW in biomedical tools; below 200 nm, you need air-free beam path.

Thermal management: Picosecond UV amplifiers fight multiphoton absorption by stretching pulses or making spot bigger.

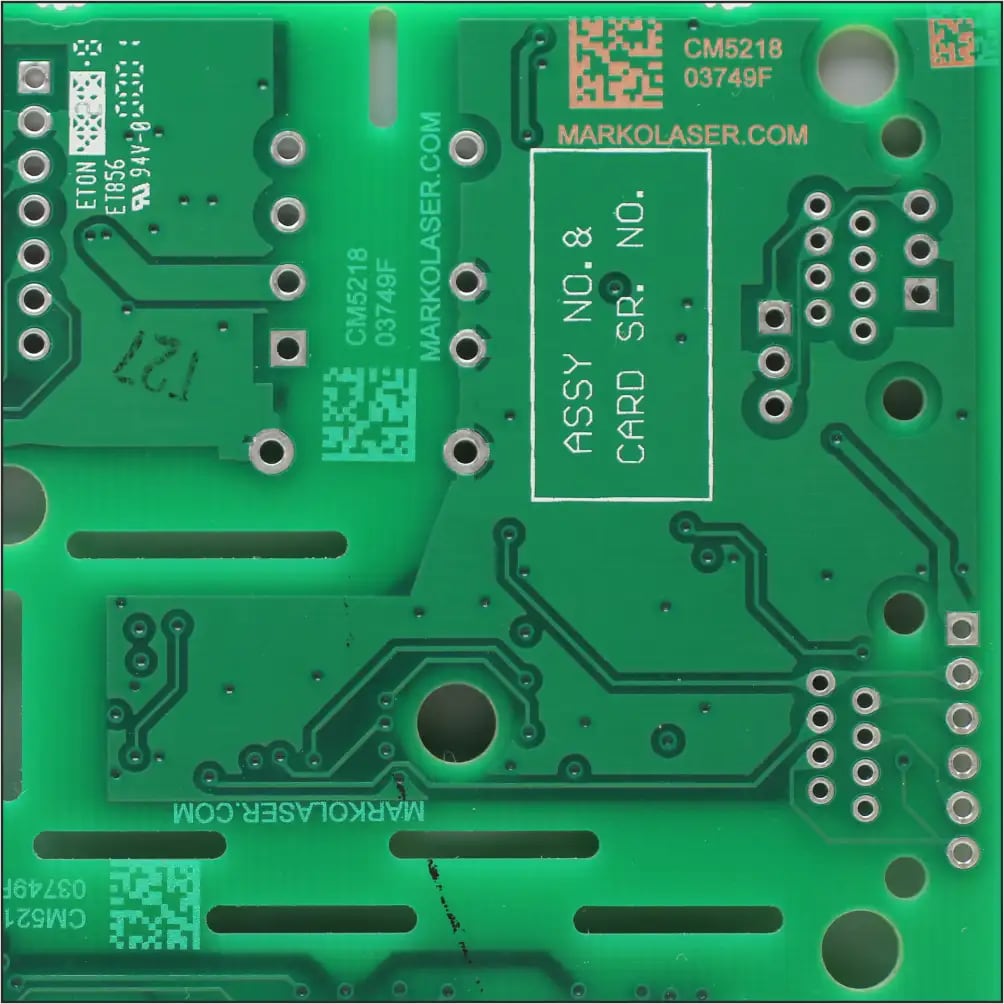

Cold ablation: 355 nm or 266 nm beams take off polymers, glass, an thin metals—with sub-5 µm kerf an almost no heat-affected zones.

PCB via drilling: KrF/ArF excimer lasers drill 50–75 µm vias through polyimide an copper stacks—over 5000 vias per second on smartphone HDI boards.

Marking & coding: 355 nm nanosecond lasers (like Nano Mark UV coders) make high-contrast marks on HDPE, PET, an blister foil—no additives needed, replacing inkjet ribbons.

Laser-induced breakdown spectroscopy (LIBS): Short UV pulses make hotter plasmas an stronger atomic lines—great for sorting alloys.

UV Raman & UVRR: 248 nm or 266 nm excitation cuts out fluorescence—letting scientists study protein structures an detect trace pollutants.

Photolithography: ArF 193 nm scanners make < 20 nm feature; F₂ 157 nm research pushed limits to ~70 nm before EUV took over.

Wafer inspection: 266 nm pulsed lasers show reticle defects; 355 nm CW sources run dark-field inspection.

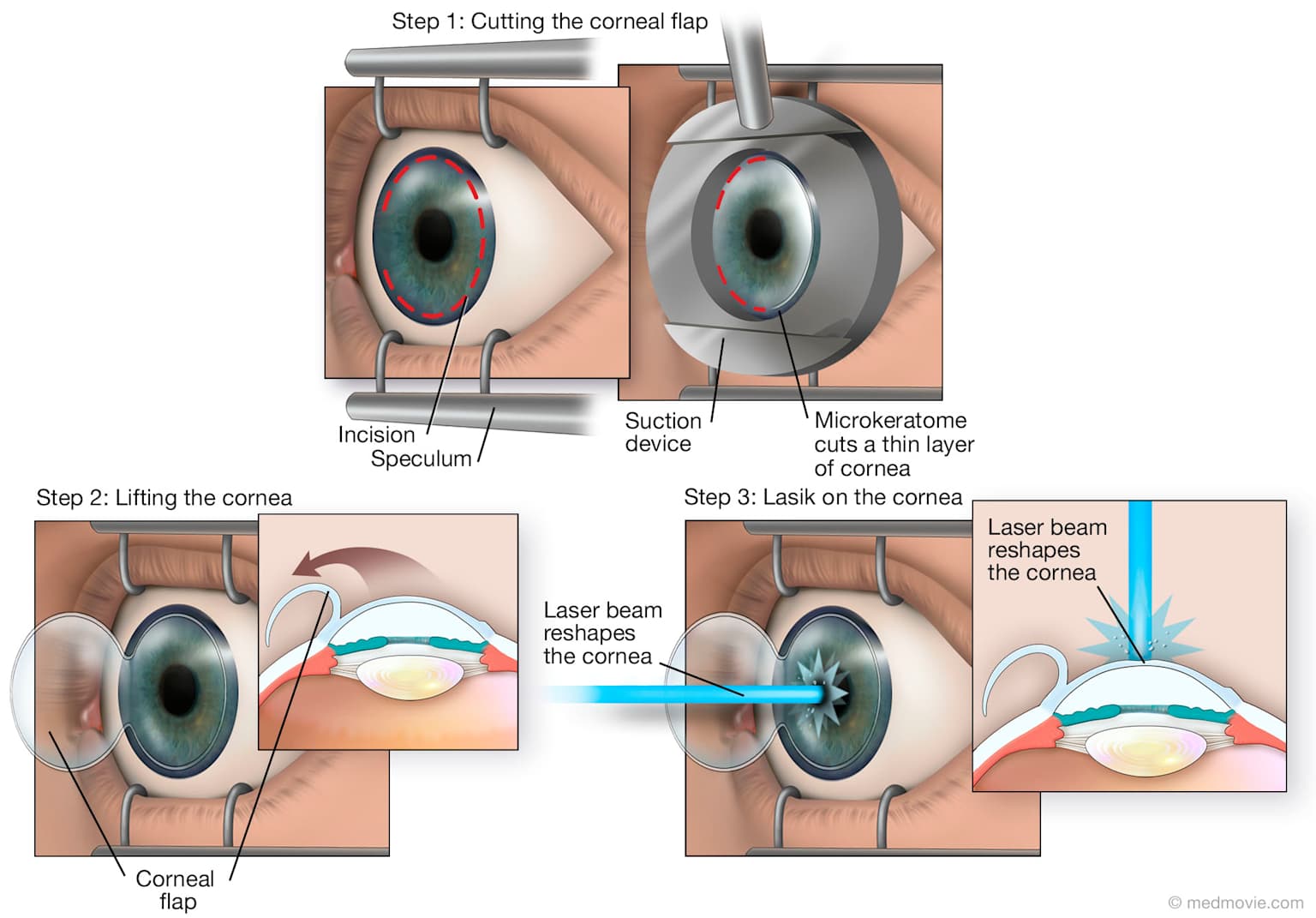

LASIK & PRK: ArF excimer pulses reshape corneal stroma—with < 1 µm accuracy an almost no thermal load.

Laser microdissection: 355 nm Q-switched beams pick out single cells for proteomics—hardly any DNA damage.

Table-top high-harmonic generators make attosecond extreme-UV pulses—perfect for ultrafast chemistry.

Fiber-pumped deep-UV sources aim for 229 nm—used to cool strontium for quantum information.

UV radiation carries higher risks for eyes an skin:

Eyes: Corneal photokeratitis (< 315 nm) an retinal burns (UV-A).

Skin: Erythema an higher carcinoma risk from long-term exposure.

You must use class-1 enclosures, interlocks, UV-blocking eyewear, an low-outgassing materials in UV Laser workspaces.

Advances in wide-bandgap semiconductors, fluoride crystals, an nonlinear materials keep making UV Lasers smaller—while boosting power an lifetime. At the same time, precision industries are switching from consumable printing an mechanical tools to maintenance-free, high-contrast UV Lasers—like Nano Mark’s compact coders for food, pharma, an electronics packaging. With steady progress, ultraviolet photonics will keep advancing nanofabrication, quantum technologies, an minimally invasive medicine.

For detailed specs on Nano Mark UV an fiber systems, go to product pages for UV, CO₂, an fiber laser coders.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China